The core mechanical properties of copper and copper alloys are directly reflected by the level of their hardness values, and the mechanical properties of a material determine its strength, wear resistance, and deformation resistance.There are usually the following test methods for detecting the hardness of copper and copper alloys:

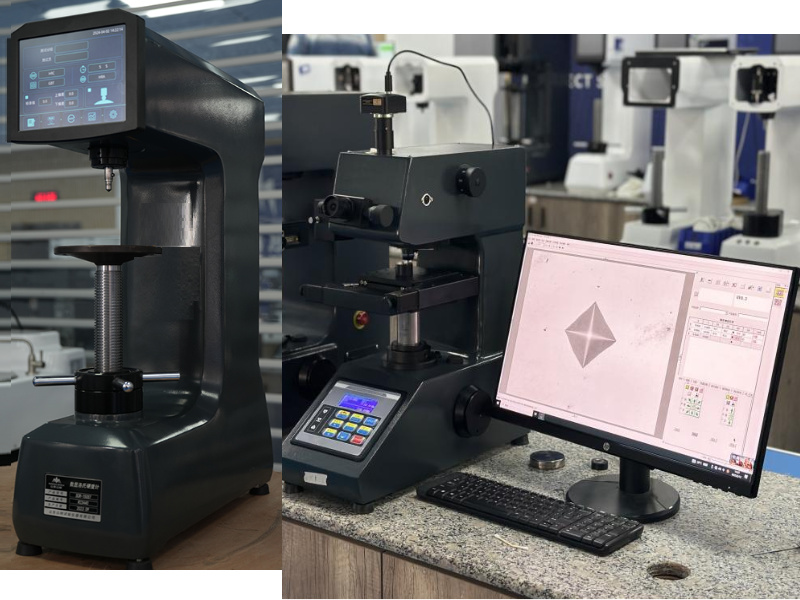

1.Brinell Hardness Testing Method: It follows the hardness testing provisions specified in the international standard ISO 6506-1:2014 Metallic Materials – Brinell Hardness Test. This testing method is applicable to pure copper, brass, bronze, or relatively soft copper materials; for example, the hardness testing requirement for cast copper alloys is Brinell Hardness (HBW) testing.

2.Depending on the different hardness and thickness of copper, Rockwell or Vickers hardness testing methods may also be adopted. For example, brass can be tested using the HRB scale (in accordance with the international standard ISO 6506-1:2014 Metallic Materials – Rockwell Hardness Test – Part 1: Test Method), and brass sheets can be tested using the HV Vickers hardness scale. The hardness standards for brass vary according to its different compositions and heat treatment states, and evaluation needs to be conducted based on specific test methods and standards.

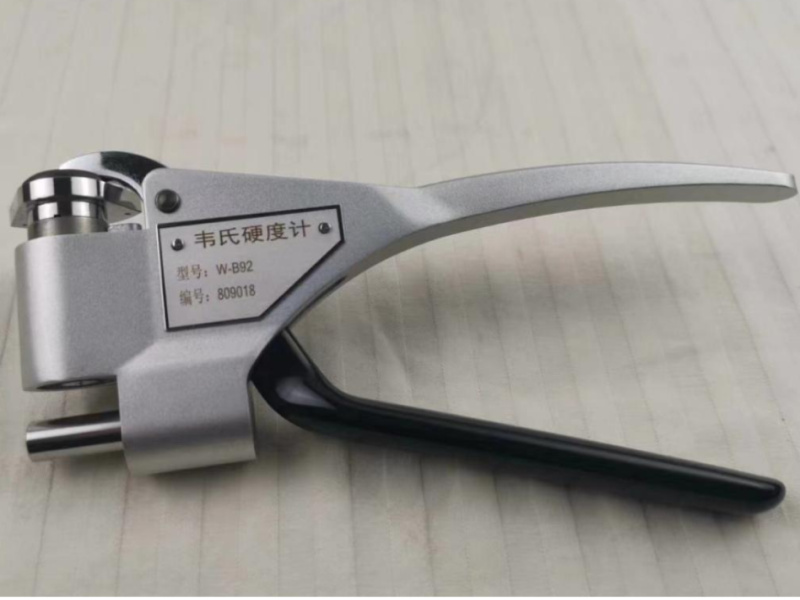

3.Portable Webster Hardness Testing Method: In accordance with the national standard GB/T 32660.1-2016 Metallic Materials – Webster Hardness Test – Part 1: Test Method, this testing method is applicable to copper and its alloy sheets with relatively thin specimen thickness.

The above respective testing standards constitute the technical basis for the testing of copper and its alloys. When testing products, we select different testing methods based on the material type and application.

Post time: Oct-17-2025