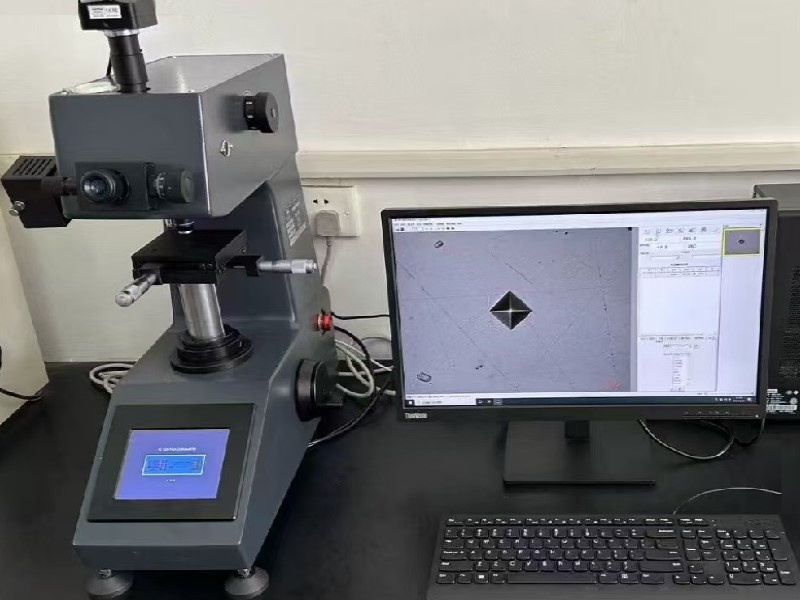

There are many types of metallic coatings. Different coatings require the different test forces in microhardness testing, and test forces cannot be used randomly. Instead, tests should be conducted in accordance with the test force values recommended by standards. Today, we will mainly introduce micro Vickers hardness testing of zinc coatings or zinc-aluminum-magnesium alloy coatings applied on steel.

1.Preparing high-quality metallographic samples of zinc coatings (or aluminum-magnesium coatings) is the first step in coating testing. The preparation of zinc coating samples involves multiple steps, including sampling, mounting, and pre-grinding and polishing. The purpose of preparing such samples is to grind the cross-sectional surface of the workpiece into a smooth, flat surface that allows clear visualization of Vickers indentations, facilitating accurate measurement of indentation dimensions to obtain hardness values.

2.For hardness testing of zinc coatings: since zinc coatings are relatively thick, hardness tests can be performed with different test forces. On the same sample, the smaller the test force applied, the smaller the indentation size; conversely, the larger the test force, the larger the indentation size. If the coating around the indentation shows signs of cracking or deformation, a smaller test force should be selected. This process is repeated until the coating around the Vickers indentation remains relatively intact without deformation—this test force level is the appropriate one for the sample.

2.1 Different coating thicknesses correspond to specific test force ranges, which is crucial for avoiding distortion of test results. The following is a reference for test force selection for common coatings (zinc plating, chromium plating), applicable to micro Vickers hardness testers (HV):

| Coating Type | Coating Thickness (μm) |

Recommend Test Force (gf) |

Corresponding HV Scale |

Key Precautions |

| Zinc Plating |

5 ~ 15 | 25 ~ 50 | HV0.025, HV0.05 | Zinc plating is relatively soft (usually HV50~150); small force prevents excessive indentation. |

| Zinc Plating |

15 ~ 50 | 50 ~ 100 | HV0.05, HV0.1 | As thickness increases, force can be appropriately raised to ensure clear indentation edges. |

| Chromium Plating |

1 ~ 5 | 10 ~ 25 | HV0.01, HV0.025 | Hard chromium (HV800~1200) has high hardness; small force prevents indenter damage. |

| Chromium Plating |

5 ~ 20 | 25 ~ 100 | HV0.025, HV0.1 | When thickness >10μm, HV0.1force balances accuracy and efficiency. |

| Composite Coating |

<5 | ≤25 | HV0.01, HV0.025 | For coatings like zinc-nickel alloy and chromium-nickel alloy, strictly prevent indentation from penetrating the coating. |

2.2 Other Key Influencing Factors

In addition to thickness, the following two factors will further modify the selection of test force, and need to judge on base of actual scenarios:

Coating Hardness Range:

Soft coatings (e.g., zinc plating, HV < 200): If the test force is too small, indentations may become blurred due to plastic deformation of the coating. It is recommended to select the upper limit of the recommended range (such as., thickness 10 μm,choose 50gf test force).

Hard coatings (e.g., chromium plating, HV > 800): The high hardness results in small indentations, so the test force should not be too small (such as, thickness 5 μm,choose 25gf test force) to prevent the measurement error of the indentation diagonal from exceeding ±5%.

2.3 Requirements of Standards and Specifications

Different industries have clear standards. For example:

The automotive industry commonly adopts ISO 14577 (Instrumented Indentation Test), which allows adjusting the force value according to the coating thickness;

General industry refers to ASTM E384, which requires that the indentation diagonal is ≤ 1/2 of the coating thickness and ≥ 10 times the radius of the indenter tip (to avoid the tip effect).

In conclusion, the selection of test force for micro-Vickers hardness testing of metallic coatings shall follow the logic of “thickness first, hardness adjustment, and standard guarantee”:

First, determine the test force range based on the coating thickness (refer to the table above);

Adjust the force value according to the hardness of the coating (select the upper limit for soft coatings and the lower limit for hard coatings);

Finally, align with industry standards (such as ISO 14577 and ASTM E384) to ensure the validity of test results.

Post time: Sep-03-2025