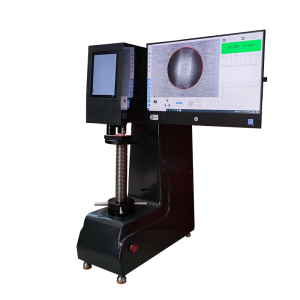

HRD-45 Dial gauge Motor-driven Superficial Rockwell hardness tester

Determine the Rockwell hardness of ferrous metals, non-ferrous metals, and non-metallic materials; wide range of applications, suitable for quenching

Rockwell hardness measurement for heat treatment such as quenching and tempering; curved surface measurement is stable and reliable.

Friction-free spindle ensures test force accuracy;

The loading and unloading test force is completed electrically without human operating error;

Independent suspended weights and core spindle system make the hardness value more accurate and stable;

The dial can directly read the HRA, HRB and HRC scales;

| Measuring range | 71-94HR15N, 42-86HR30N, 20-77HR45N67-93HR15T, 29-82HR30T, 10-72HR45T |

| Initial test force | 3kgf (29.42N) |

| Total test force | 15kgf (147.1N), 30kgf (294.2N), 45kgf (441.3N) |

| Measuring scale | HRA, HRB, HRC scales can be read directly on the dial |

| Optional scales | HRD, HRF, HRG, HRH, HRE, HRK, HRL, HRM, HRP, HRR, HRS, HRV |

| Hardness value reading method | Rockwell dial reading; |

| Test force loading method | Motor-driven completion of loading test force, maintaining test force, and unloading test force; |

| The maximum height allowed for the specimen | 175mm; |

| Distance from center of indenter to machine wall | 135mm; |

| Hardness resolution | 0.5HR; |

| Power supply voltage | AC220V±5%, 50~60Hz |

| Overall dimensions | 450*230*540mm; |

| Packing size | 630x400x770mm; |

| Weight | 80KG |

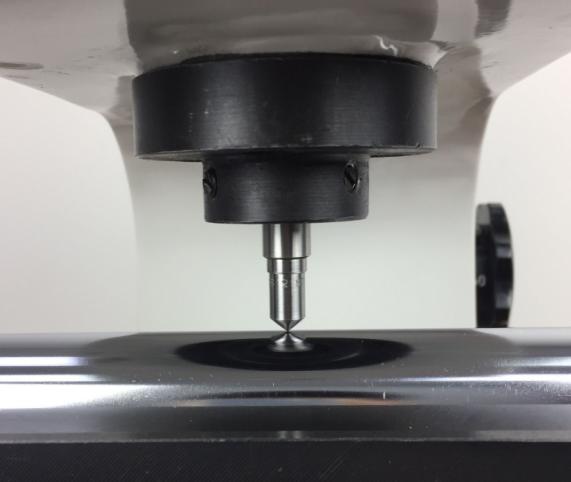

| Main machine: 1 | 120° diamond indenter: 1 |

| Φ1.588 steel ball indenter: 1 | large flat working table: 1 |

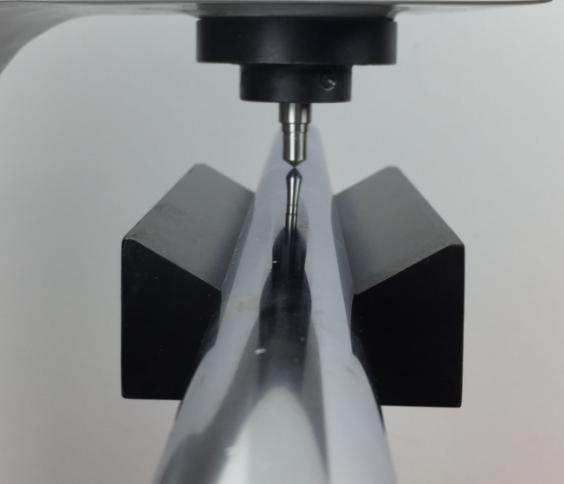

| Small flat workbench: 1 | V-shaped workbench: 1 |

| 70~85 HR30T hardness block | 80~90 HR15N hardness block |

| 65~80 HR30N hardness block | Power cord: 1 |

| Screwdriver: 1 | User manual: 1 copy |