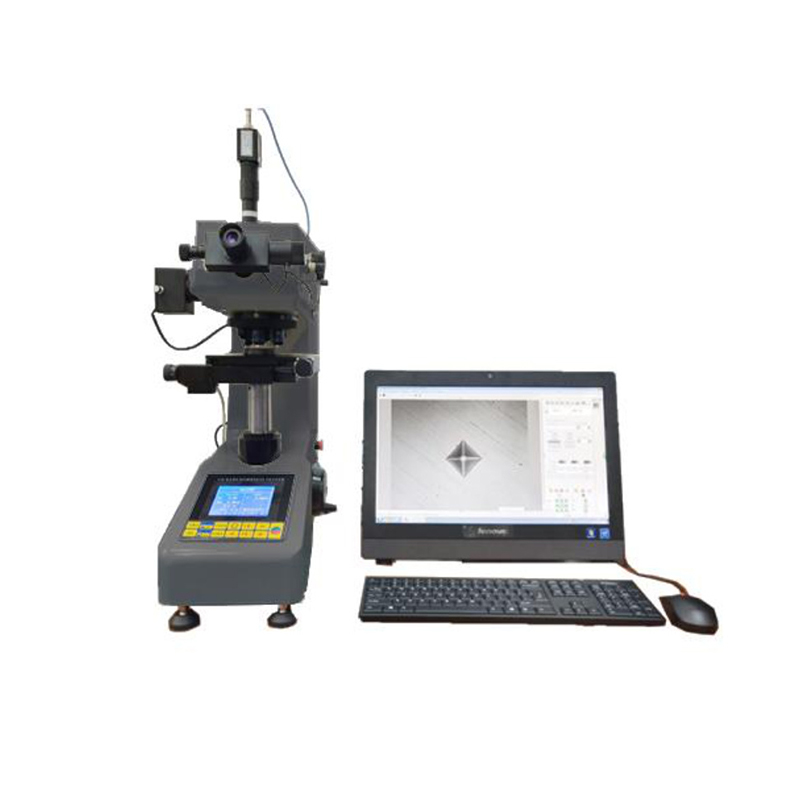

ZHV2.0 Fully Automatic Micro Vickers and Knoop Hardness Tester

This instrument is widely used in such fields as metallurgy, electro-mechanics and mould, etc. It can analyze and measure the hardness value of specimen or surface hardened layers, hence it is an absolutely indispensable instrument for analysis and test in the field of mechanics machining or measurement of high precision parts.

By means of RS232 interface to connect with computer, move X axis and Y axis with different step length selected, the instrument is specially fit to measure the hardness value of carburized layer of specimen or the depth of hardened layer.

Applying with different loads, different kinds of specimens can be tested. And it can form and store the graph-text reports. It is simple to operate and easy to use for clients.

This software can control such operations of hardness tester as: rotation of motorized turret, light luminosity, dwell time, movement of loading table, application of loading and automatic focusing, etc, it can enable the PC computer to control the hardness tester with command as well.

At the same time, the hardness tester can feedback the information of command executed. It enables all the connecting units to communicate with each other.

With friendly user interface, humanization, stability, reliability and very high precision position of mechanics, this software will completely meet the needs of test requirements.

This instrument can not only test single-point of Vickers hardness indentation, but also can test continuous multi-point of Vickers hardness indentations after automatically loadings.

And it can make out the curve of hardness distribution as well. According to this curve, the accordance depth of hardened layer can be calculated out.

All the measuring data, calculating results and indentation images may form graph-text reports which can be printed out or stored.

Software configurable: According to user's requirements, iVision-HV can be configured as the base version (with camera only), the turret control version that commands the Vickers hardness test machine, the semi-automatic version with the motorized XY sample stage, and the full-automatic version that controls the Z-axis motor

OS supported: Windows XP, Windows Vista, Windows 7 and 8 32 and 64 bits

Fully automatic in test and measurement: With a single button click, system automatically moves to test points by predefined test pattern and path, tests, auto-focuses, and automatically measures

Automatic sample contour scan: With XY sample stage system can automatically scan the sample contour for specialized tests that requires locating test points relative to sample contour

Manual correction: Test result can be manually corrected with a simple mouse drag move

Hardness vs. depth curve: Automatically plots the hardness depth profile and calculates the Case Hardness Depth

Statistics: Automatically calculates the average hardness and its standard deviation

Data archiving: Test results including measurement data and measurement images can be saved in a file

Reporting: Test results including measurement data, indentation images, and hardness curve can be outputted to Word or Excel document. User can customize the report template.

Other functions: Inherits all the functions of iVision-PM Geometry Measurement Software

Measuring range:5-3000HV

Test force: 2.942,4.903,9.807, 19.61, 24.52, 29.42, 49.03,98.07N (0.3,0.5,1,2, 2.5, 3, 5,10kgf)

Hardness scale:HV0.3,HV0.5,HV1, HV2, HV2.5, HV3, HV5,HV10

Lens/indenters switch: auto turret

Reading microscope: 10X

Objectives: 10X(observe), 20X (measure)

Magnifications of the measuring system:100X, 200X

Effective field of view: 400um

Min. Measuring Unit: 0.5um

Light source: Halogen lamp

XY table: dimension:100mm*100mm Travel: 25mm*25mm Resolution:0.01mm

Max. height of test piece:170mm

Depth of throat:130mm

Power supply:220V AC or 110V AC, 50 or 60Hz

Dimensions:530×280×630 mm

G.W./N.W.: 35Kgs/47Kgs

|

Main unit 1 |

Horizontal Regulating Screw 4 |

|

10x Reading microscope 1 |

Level 1 |

|

10x, 20x objective 1 each (with main unit) |

Fuse 1A 2 |

|

Diamond Vickers Indenter 1 (with main unit) |

Halogen Lamp 1 |

|

XY table 1 |

Power Cable 1 |

|

Hardness Block 700~800 HV1 1 |

Screw Driver 1 |

|

Hardness Block 700~800 HV10 1 |

Internal hexagonal wrench 1 |

|

Certificate 1 |

Anti-dust Cover 1 |

|

Operation Manual 1 |