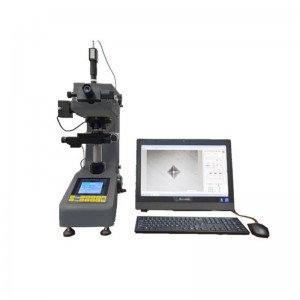

MHV-1000B/A Large Screen Digital Display Micro Vickers Hardness Tester

1.Made with a unique and precision design in the field of mechanics, optics and light source. Able to produce a clearer image of indentation and hence a more precise measurement.

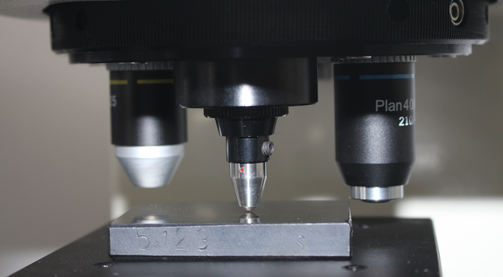

2. By means of a 10Χ objective and a 40Χ objective and a 10Χ microscope for measurement.

3. It shows measuring method, the testing force value, the indentation length, hardness value, the dwell time of the testing force, as well as the number of measurement on the LCD screen.

4. During the operation, put in the diagonal length with the keys on the keyboard, and the built-in calculator automatically calculates the hardness value and shows it on the LCD screen.

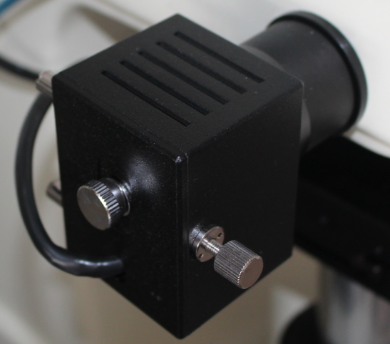

5. The tester has a threaded interface that can be linked to the digital camera and CCD pickup camera.

6. The light source of the tester is firstly and uniquely adopted cold light source, and hence its life can reach 100000 hours. The user also can select halogen lamp as light source according to their requirement.

7. The CCD Automatically Image Measuring Device can be equipped on present tester according to user’s requirement. (optional)

8. The LCD Video Measuring Device can be equipped on the present tester according to user’s requirement. (optional)

9. According to user’s requirement , the rester also can measure Knoop hardness value after equipping a Knoop indenter.

Measuring range:5HV~3000HV

Test force:0.098,0.246,0.49,0.98,1.96,2.94,4.90,9.80N (10,25,50,100,200,300,500,1000 gf)

Max. height of test piece:100mm

Depth of throat:135mm

Lens/indenters with:MHV-1000B:With Hand Turret

MHV-1000A: With Auto Turret

Carriage Control:Automatic(loading /holding-up of the load/unloading)

Reading microscope: 10X

Objectives: 10x(observe) , 40x(measurement)

Total amplification: 100×,400×

Data output: Built-in printer, RS232 Interface

Dwell Time of the Test Force:0~60s (5 seconds as a unit)

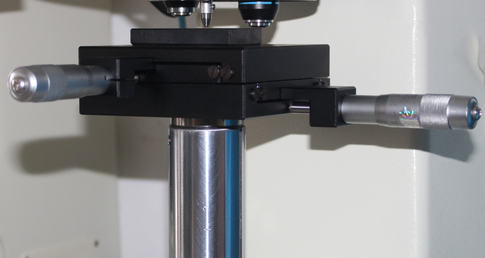

Dimension of the XY Table: 100×100mm

Travel of the XY Table: 25×25mm

Light source/Power Supply:220V,60/50Hz

Net Weight/Gross Weight:30Kg/47kg

Dimension:480×325×545mm

Package dimension: 600 × 360 × 800 mm

G.W/N.W: 31KGS/44KGS

|

Main unit 1 |

Horizontal Regulating Screw 4 |

|

Reading microscope 1 |

Level 1 |

|

10x, 40x objective 1 each (with main unit) |

Fuse 1A 2 |

|

Diamond Micro Vickers Indenter 1 (with main unit) |

Halogen Lamp 1 |

|

Weight 6 |

Power Cable 1 |

|

Weight Axis 1 |

Screw Driver 2 |

|

XY table 1 |

Hardness Block 400~500 HV0.2 1 |

|

Flat Clamping Test Table 1 |

Hardness Block 700~800 HV1 1 |

|

Thin Specimen Test Table 1 |

Anti-dust Cover 1 |

|

Filament Clamping Test Table 1 |

Operation manual 1 |

|

Certificate |

|

|

Knoop Indenter |

CCD Image Measuring System |

|

Knoop Hardness Test Blocks |

Metallographic Specimen Mounting Press |

|

Metallographic Specimen Cutter |

Metallographic Specimen Polisher |