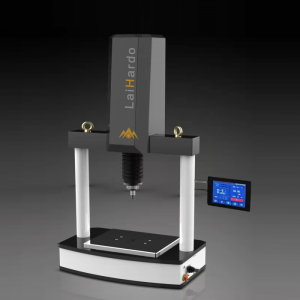

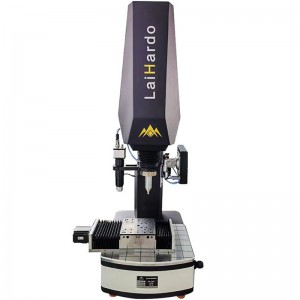

HRS-150ND Digital Rockwell Hardness Tester (Convex Nose Type)

HRS-150ND convex nose Rockwell hardness tester adopts the latest 5.7-inch TFT touch screen display, automatic test force switching; direct display of residual depth h according to CANS and Nadcap certification requirements; can view raw data in groups and batches; test data can be printed by group through optional external printer, or optional Rockwell host computer measurement software can be used to collect test data in real time. It is suitable for hardness determination of quenching, tempering, annealing, chilled castings, forgeable castings, carbide steel, aluminum alloy, copper alloy, bearing steel, etc.

This product adopts a special indenter structure (commonly known as the "convex nose" structure). In addition to the tests that can be completed by the general traditional Rockwell hardness tester, it can also test the surfaces that cannot be measured by the traditional Rockwell hardness tester, such as the inner surface of annular and tubular parts, and the inner ring surface (optional short indenter, the minimum inner diameter can be 23mm); it has the characteristics of high test accuracy, wide measurement range, automatic loading and unloading of the main test force, digital display of measurement results and automatic printing or communication with external computers. There are also powerful auxiliary functions, such as: upper and lower limit settings, out-of-tolerance judgment alarm; data statistics, average value, standard deviation, maximum and minimum values; scale conversion, which can convert test results into HB, HV, HLD, HK values and strength Rm; surface correction, automatic correction of cylindrical and spherical measurement results. It is widely used in the detection, scientific research and production of measurement, machinery manufacturing, metallurgy, chemical industry, building materials and other industries.

|

model |

HRS-150ND |

|

Rockwell initial test force |

10kgf(98.07N) |

|

Rockwell total test force |

60kgf(588N) 100kgf(980N) 150kgf(1471N) |

|

Rockwell Hardness Scale |

HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HRL, HRM, HRR, HRP, HRS, HRV |

|

Rockwell test range |

HRA: 20-95 , HRB: 1 0-100, HRC: 1 0-70, HRD: 40-77, HRE: 70-100, HRF: 60-100, HRG: 30-94, HRH: 80-100, HRK: 40-100, HRL: 50-115, HRM: 5 0 -115, HRR: 50-115 |

|

Test force switching |

Stepper motor automatic switching |

|

Hardness value resolution |

0.1 / 0.01HR optional |

|

show |

5.7-inch TFT display touch screen, intuitive UI interface |

|

Residual depth of indentation |

hReal-time display |

|

Menu Text |

Chinese/English |

|

How to operate |

TFT touch screen |

|

Testing Process |

Automatic completion with text prompts |

|

Main test force loading time |

2 to 8 seconds can be set |

|

Dwell time |

0-99s, and can set and store initial test force holding time, total test force holding time, elastic recovery holding time, segmented display time; accompanied by color change countdown |

|

Accessibility |

Upper and lower limit settings, out-of-tolerance judgment alarm; data statistics, average value, standard deviation, maximum value, minimum value; scale conversion, test results can be converted into Brinell HB, Vickers HV, Leeb HL, surface Rockwell hardness and tensile strength Rm/Ksi; surface correction, automatic correction of cylindrical and spherical measurement results |

|

Implement the latest standards |

GB/T230-2018, ISO6508, ASTM E18, BSEN10109, ASTM E140, ASTM A370 |

|

Maximum test space |

270mm vertically, 155mm horizontally |

|

Test parts type |

Flat surface; cylindrical surface, minimum outer diameter 3mm; inner ring surface, minimum inner diameter 23mm |

|

Data storage capacity |

≥1500 groups |

|

Data browsing |

Can browse by group and detailed data |

|

Data Communication |

Can be connected to a micro printer via the serial port (optional printer);Data transmission can be realized with PC through serial port (optional Rockwell host computer measurement software) |

|

power supply |

220V/110V, 50Hz, 4A |

|

size |

715mm×225mm×790mm |

|

net weight |

100kg |

|

name say |

number quantity |

name say |

number quantity |

|

Instrument |

1 unit |

Diamond Rockwell Indenter |

1 |

|

φ1.588mm ball indenter |

1 |

Round sample test bench, V-shaped test bench |

1 each |

|

Standard hardness block HRA |

1 block |

Standard hardness block HRBW |

1 block |

|

Standard hardness block HRC |

3 pieces |

Pressure head mounting screw |

2 |

|

Power cord |

1 root |

Level adjustment screw |

4 |

|

Dust cover |

1 |

Product Certificate |

1 serving |

|

Product Brochure |

1 serving |

|