LHMICV5100 Fully Automatic Upright Metallurgical Microscope

All operations are designed according to ergonomic principles to minimize operator fatigue. Its modular component design allows for flexible combination of system functions. It encompasses various observation functions, including bright-field, dark-field, oblique illumination, polarized light, and DIC differential interferometry, with functions selectable based on specific applications.

Supports a world-leading 25mm ultra-wide field of view, bringing you a brand-new wide-viewing experience. A wider range of diopter adjustment can meet the needs of more users.on specific applications.

The bright-field and dark-field semi-apochromatic objectives are made with carefully selected high-transmittance lenses and advanced coating technology to truly reproduce the natural colors of the sample; the semi-apochromatic design has excellent color correction performance, improving the contrast and clarity of the observed image.

The polarization system includes a polarizer insert and an analyzer insert, which can perform polarized light detection. In semiconductor and PCB inspection, it can eliminate stray light and make details clearer.

The 360° rotating analyzer allows for convenient observation of the specimen's appearance under light with different polarization angles without moving the specimen.

● The XY high-precision motorized stage, combined with a closed-loop control system , enables full-size image scanning and high-performance image synthesis, ensuring seamless integration of multiple fields of view.

● It supports custom scanning paths, adapts to irregular samples, and improves the success rate of splicing complex surfaces.

● The Z-axis is electrically powered, enabling automatic image focusing.

The lever at the front of the illuminator makes switching between bright and dark fields easier and features a neutral density filter linkage function. This prevents the user's eyes from being stimulated by strong light when switching from dark to bright fields, improving user comfort.

A multi-aperture objective converter allows for more reasonable and continuous observation at low, medium, and high magnifications of the same specimen at different observation points.

| Optical system | Infinity-corrected optical system |

| Observation tube | 30° tilt, infinity hinged three-way observation tube, interpupillary distance adjustment: 50mm~76mm, two-level beam splitting ratio, binocular:trino = 100:0 or 0:100 |

| eyepiece | High eyepoint, wide field of view plan eyepiece PL10X / 25mm, adjustable diopter. |

| Light and dark fieldsSemi-complex objective lens | LMPLFL 5X /0.15 BD DIC WD13.5mmLMPLFL10X/0.30 BD DIC WD9.0mmLMPLFL20X/0.5 BD DIC WD2.5mmLMPLFL50X/0.80 BD WD1.0mmLMPLFL100X / 0.90 BD WD 1.0mm |

| converter | 6-hole converter for light and dark fields, with DIC slot |

| frame | The camera features a reflector frame and a low-position coaxial coarse and fine focusing mechanism . The coarse adjustment travel is 25mm , and the fine adjustment accuracy is 0.001mm. It includes an anti-slip adjustment tension device and a random upper limit switch. |

| Lighting system | Bright-field and dark-field reflective illuminator with variable aperture diaphragm, field diaphragm, and center adjustable; with bright-field and dark-field illumination switching device; with color filter slot and polarizer/analyzer slot. |

| lamp room | 12V 100W halogen lamp room, suitable for both transmission and reflection, available for pre-order. |

| Z-axis | Autofocus |

| Electric platform | Platform travel: Horizontal direction * Vertical direction = 80 * 60 (unit: mm)Screw lead: 2000μmXY repeatability accuracy: within ± 2 μmZ-axis repeatability: within ± 1 μmResolution at 16 subdivisions: 0.625μm per step

Stepper motor step angle: 1.8° Rated operating current: 1.0A per shaft (powered by 24V) Maximum load: ≥5kg Maximum round-trip clearance: 2 micrometers Maximum sample height is 25mm (other heights can be customized). |

| Drive control box | It uses a standard RS232 serial port to communicate with a PC (115200 baud rate).Serial port control allows setting the motor's speed, distance, and direction of movement. |

| Other attachments | Polarizer insert, 360° rotating analyzer insert, and interference filter set for reflection. |

| Analysis System | FMIA 2025 genuine metallographic analysis software and porosity software |

| camera device | 5 megapixels , 36 fps |

| 0.5X adapter lens interface, micrometer | |

| Industrial control computers | Intel i5 processor , 64GB RAM , 1TB SSD , 27-inch 4K monitor |

Our metallographic image analysis software is a brand-new system developed by our company based on the metallographic testing needs of casting enterprises, auto parts enterprises, heat treatment enterprises, bearing steel industry, power system industry, railway parts industry, and various related testing companies . In order to improve product qualification rate and help improve the testing level of various laboratories, we collected the needs and opinions of experts and teachers from various industries .

The metallographic image analysis software has undergone a complete redesign and upgrade. The system covers a large number of domestic and international metallographic testing standards, integrates quantitative and qualitative analysis, and adds depth-of-field synthesis and image field-of-view stitching functions. The interface is simple and can continuously capture multi-field-of-view images for centralized image organization and analysis. The operation is more convenient, eliminating various cumbersome steps of the previous software, making the testing faster and more efficient.

We have developed a brand-new "professional, accurate, and efficient" metallographic analysis tool system to simplify metallographic analysis.

The software system's national standard library contains hundreds of categories, basically covering commonly used metallographic standards and meeting the metallographic analysis and testing requirements of the vast majority of organizations. Relevant categories are specified and opened according to the needs of different industries to meet industry testing requirements. All modules are available free of charge for life, and standards are upgraded free of charge for life.

Given the increasing number of new materials and imported grades, materials and evaluation standards that are not yet included in the software can be customized and entered separately .

Advantages and functions of metallographic analysis software :

- Batch video image capture and acquisition : Batch shooting, batch naming, batch saving, batch printing with fixed magnification and other multi-image batch processing functions make the batch sample inspection process more convenient and efficient.

- Advanced camera settings: Exposure time, gain, sharpness, saturation, gamma, contrast, brightness, white balance, black balance, and other function settings.

- One-click calibration for all objectives: The calibration function has been completely upgraded, allowing you to complete the calibration of all objective parameters with a single click. Compared to the original calibration method, the new calibration method is more convenient and faster to operate.

- Image processing functions: color separation, grayscale conversion, thresholding, binarization, image enhancement, phase inversion, sharpening, scratch and smudge removal, image histogram, etc.

- Image scaling output : Features include multi-image scaling printing, custom image names, scale parameter settings, exporting to PDF/Word/Excel, and print preview.

Image measurement and archiving: A variety of measurement tools are available (including distance, angle, angle between two lines, rectangle, point-to-line distance, ellipse, polygon, parallel line distance, three-point arc, three-point circle, etc.), allowing drawing arrows, labeling text, and adding...Multiple options are available for auxiliary lines, line width, and length units; measurement data font color, size, and font style are also available; test data can be summarized and exported to Excel .

Organizational analysis function: The software library contains a diverse range of testing standards, including GB/ASTM/ISO/DIN/QC/JB/DL/TB/SS and other organizational analysis standards. Standards in the software library can be upgraded free of charge, and the software features automatic and comparative analysis capabilities.It features three metallographic grading functions: primary, secondary, and assisted. It is easy, simple, and quick to use, and provides accurate and reliable measurements.

Advanced customization features: Customized microscope motorized stage control, image confocalization, 3D light mapping, image database, etc.

Diverse report templates: Automatically generates richly illustrated metallographic analysis reports, with options for single-module or multi-module report styles. Report templates can be modified to include company logos, company names, testing procedures, and other information. Customized report templates are also available to meet your specific needs.

AI-powered tissue analysis function: A customizable AI tissue analysis module utilizes artificial intelligence to complete the entire microstructure analysis and detection process, automatically identifying and analyzing the microstructure of materials. The operation process is simple, reducing the labor intensity of personnel.Improve the efficiency of material testing.

National Standard Drawing Library: Contains hundreds of national standard drawings for customers to study and reference.

Metallography Teaching Module: Includes a metallography teaching module for customers to learn and refer to.

EDF Depth of Field Expansion Function : For samples that are uneven and cannot be aligned in focus, the software provides a dynamic EDF depth of field shooting function. By adjusting the microscope's Z-axis micro-adjustment focusing handwheel, clear details in the sample will be continuously added to the dynamic EDF display window for dynamic updates. The software automatically records clear images at different depths of field and merges them into a clear image.

Image stitching function : For customers who need to inspect a larger field of view, the software provides an image stitching function. Users can move the microscope's XY platform to achieve full-size scanning of images and high-performance image synthesis to ensure seamless connection of multiple fields of view . This meets the customer's need to capture images of larger sample fields of view and solves the embarrassment of not being able to take pictures due to insufficient microscope field of view.

It supports custom scanning paths, adapts to irregular samples, and improves the success rate of splicing complex surfaces.

The Z-axis is electrically powered, enabling automatic image focusing.

| GB/T 10561-2023 Determination of Non-metallic Inclusion Content in Steel | GB/T 34474.1-2017 Evaluation of banded structure in steel |

| GB/T 7216-2023 Metallographic Examination of Gray Cast Iron | DL/T 773-2016 Spheroidization Rating Standard for 12Cr1MoV Steel Used in Thermal Power Plants |

| GB / T 26656 - 2023 Metallographic Examination of Vermicular Graphite Cast Iron | DL / T 1422 - 2015 18Cr-8Ni Series Austenitic Stainless Steel Boiler Tube Microstructure Aging Rating Standard |

| GB/T 13299-2022 Evaluation Method for Microstructure of Steel | GB /T 3489-2015 Hard alloys - Metallographic determination of porosity and non-combined carbon |

| GB/T 9441-2021 Metallographic Examination of Ductile Iron | JB/T 1255-2014 Technical Conditions for Heat Treatment of High Carbon Chromium Bearing Steel Parts for Rolling Bearings |

| GB/T 38720-2020 Metallographic Examination of Quenched Medium Carbon Steel and Medium Carbon Alloy Structural Steel | GB / T 1299 - 2014 Tool and Die Steel |

| GB/T 224-2019 Method for Determination of Decarburized Layer Depth in Steel | GB / T 25744 - 2010 Metallographic Inspection of Carburized, Quenched, and Tempered Steel Parts |

| TB/T 2942.2-2018 ZG230-450 Metallographic Inspection of Cast Steel | GB/T13305-2008 Metallographic determination of α-phase area content in stainless steel |

| JB/T 5108-2018 Metallographic Analysis of Cast Brass | JB/T 9204-2008 Metallographic Inspection of Induction Hardened Steel Parts |

| GB /T 6394-2017 Method for Determination of Average Grain Size of Metals | GB/T 13320-2007 Steel forgings, metallographic structure rating diagrams and evaluation methods |

| JB/T7946.1-2017 Metallography of Cast Aluminum Alloys | DL/T 999-2006 Spheroidized Steel Rating Standard for Power Plants |

| JB/T7946.2-2017 Overheating of Cast Aluminum-Silicon Alloys | DL/T 439-2006 Technical Guidelines for High-Temperature Fasteners in Thermal Power Plants |

| JB/T7946.3-2017 Cast Aluminum Alloy Pinhole | DL/T 786-2001 Standard for Testing and Rating of Graphitization of Carbon Steel |

| JB/T 7946.4-2017 Metallography of Cast Aluminum Alloys | B/T 1979-2001 Low-magnification microstructure defect rating diagram for structural steel |

| GB / T 34891 - 2017 Rolling Bearings_Technical Conditions for Heat Treatment of High Carbon Chromium Bearing Steel Parts | DL/T 674-1999 Standard for Pearlite Spheroidization Rating of No. 20 Steel for Thermal Power Plants |

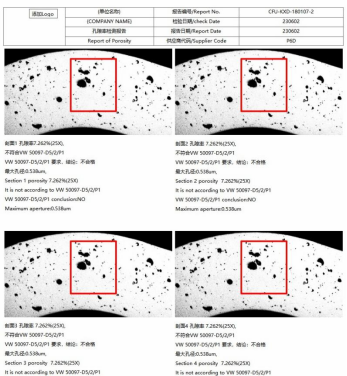

The FKX2025 porosity image analysis system uses microscopic imaging to detect the porosity of automotive parts . It is a porosity measurement system for cast aluminum used in the automotive industry , conforming to Volkswagen's VW50097 and PV6097 standards. The measurement results are accurate and reliable. It is primarily used for analyzing the casting porosity of aluminum alloys and cast iron castings , and is also suitable for porosity analysis and metallographic analysis of other materials.

The porosity image analysis software can be used with an electric stage to achieve automatic scanning , automatic focusing, automatic image stitching, automatic porosity measurement, data statistics, and report output .

Image stitching function: Set the stitching parameters and image type, click "Auto Stitch," and the image stitching will be completed automatically.

Search parameter settings: By setting the minimum area, maximum area, and threshold, a full-map search can be performed to find all pores within the set parameters of the entire map.

Image selection: Provides selection tools such as rectangle, polygon, circle, square, and triangle. After the selection is completed, the software automatically performs a porosity analysis on the selected area.

Pore analysis: It can analyze data such as the perimeter, area, major axis, minor axis, equivalent circle diameter, aspect ratio, and roundness of each pore.

Geometric measurement : A variety of measuring tools can be used for dimensional

Data statistics and report generation: It can statistically analyze detailed parameter data for each pore and generate two report modes, VW50093 or VW50097.