Origin of Vickers hardness tester

Vickers hardness is a standard for representing material hardness proposed by Robert L. Smith and George E. Sandland in 1921 at Vickers Ltd. This is another hardness testing method following the Rockwell hardness and Brinell hardness testing methods.

Principle of Vickers hardness tester:

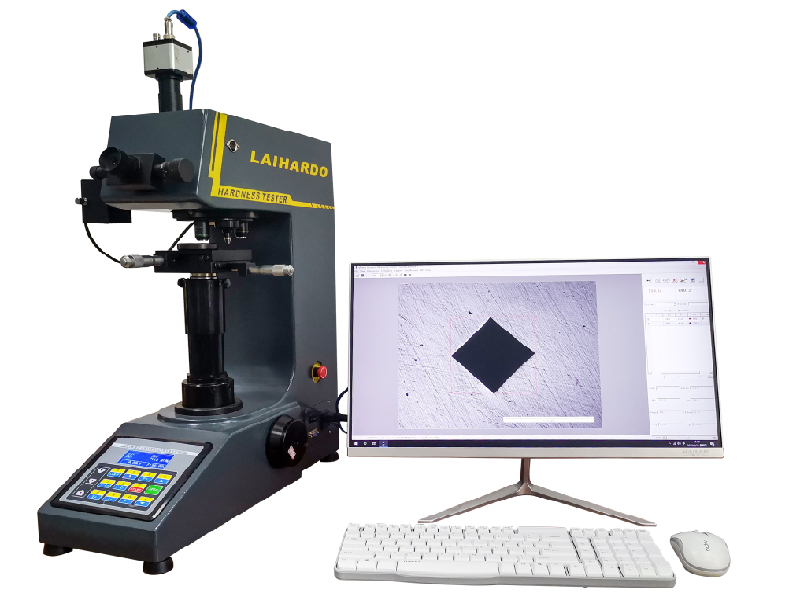

The Vickers hardness tester uses a load of 49.03~980.7N to press a square conical diamond with a relative angle of 136 ° into the surface of the material. After holding it for the specified time, the Vickers hardness value is calculated by measuring the diagonal length of the indentation and using the formula.

The load application range of the following three types of Vickers (micro Vickers):

The Vickers hardness tester with a load of 49.03~980.7N is suitable for hardness measurement of larger workpieces and deeper surface layers.

Low load Vickers hardness, test load<1.949.03N, suitable for hardness measurement of thinner workpieces, tool surfaces, or coatings;

Micro Vickers hardness, test load<1.961N, suitable for hardness measurement of metal foils and extremely thin surface layers.

In addition, equipped with a Knoop indenter, it can measure the Knoop hardness of brittle and hard materials such as glass, ceramics, agate, and artificial gemstones.

Advantages of Vickers hardness tester:

1. The measurement range is wide, from software metals to superhard metals, and can be detected, ranging from a few to three thousand Vickers hardness values.

2. The indentation is small and does not damage the workpiece, which can be used for hardness testing on workpieces that cannot be damaged on the surface of the workpiece

3. Due to its small testing force, the minimum testing force can reach 10g, which can detect some thin and small workpieces

Disadvantages of Vickers hardness tester:

Compared to the Brinell and Rockwell hardness testing methods, the Vickers hardness test has requirements for the surface smoothness of the workpiece. Some workpieces require polishing, which is time-consuming and labor-intensive

Vickers hardness testers are relatively precise and are not suitable for use in workshops or on site, and are mostly used in laboratories.

Shandong Shancai Vickers hardness tester series (picture for Wang Songxin)

1. Economic Vickers hardness tester

2. Digital display and touch screen Vickers hardness tester

3. Fully automatic Vickers hardness tester

Post time: Sep-07-2023