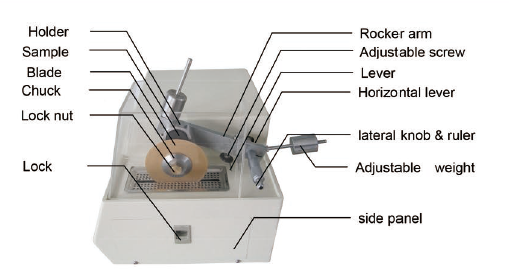

LDQ-150 Low & Medium Speed Precision Cutting Machine

*LDQ-150 Low & Medium speed precision cutting machine adopts advanced controller with compact structure, reliability and anti-interference ability.

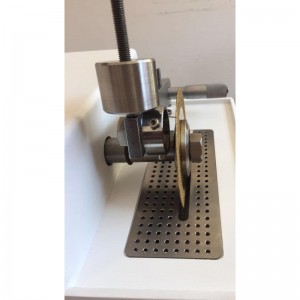

*The machine applies to all kinds of materials ,especially suitable for artificial crystals with high values.

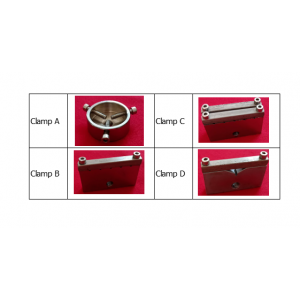

*The equipment is equipped with four kinds of fixtures ,such as A,B,C,D device, which can make the processed objects in the best angle positioning cutting.

*There is a limit switch on the machine, that can realize the cutting operation without anybody.

*Spindle operation precision is high, and can precisely fine-tune the horizontal feed position of the processed objects, automatic shutdown after cutting.

* Machine body very small not to take many space.

*High positioning accuracy

*Wide speed range

*Strong cutting capacity

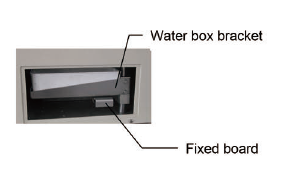

*Built-in cooling system

*Feed rate can be preset

*Menu control, touch screen and LCD display

*Automatic cutting

*enclosed cutting chamber with safety switch.

| Cutting Wheel Size | External diameter100mm-150mm

Internal diameter 20mm |

| Chuck External diameter | 48mm |

| Travel | 25mm |

| Shaft Speed | 0-1500rpm/min |

| Dimension | 520×430×390mm |

| Weight | 33Kg |

| Motor | 400W /AC220V/110V/ |

| Water tank | 0.4 L |

| The machine | 1pc | Slick rod of weight | 2pcs |

| Attachment box | 1pc | Chunk for grinding wheel | 1set |

| Litter tank (with machine) | 1pc | Buckler (with machine) | 1pc |

| Specimen holder for slice | 1pc | Cutting wheel φ100mm | 1pc |

| Specimen holder for circular | 1pc | Locking handle | 1pc |

| Dual specimen holder for slice | 1pc | Power cord | 1pc |

| Spanner | 1pc | Locking screw of principal axis | 1pc |

| Specimen holder for mounting materials | 1pc | Certificate | 1pc |

| Weight A | 1pc | Manual | 1pc |

| Weight B | 1pc |