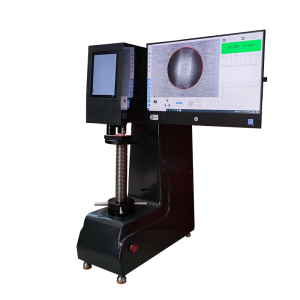

XHRS-150S Touch Screen Rockwell Hardness Tester

Hardness Conversion

Output-Printing

Electronic driven, no weight control

1.Good reliability, excellent operation and easy watching;

2. Electronic driven, simple structure, no weight using.

3. Can connect PC to output

4. Conversion different hardness scales;

Suitable for quenching, quenching and tempering, annealing, chilled castings, malleable castings, hardness determination of hard alloy steel, aluminum alloy, copper alloy, bearing steel, etc. It is also suitable for surface hardened steel, material surface heat treatment and chemical treatment layer, copper, aluminum alloy, thin plate, galvanized, chrome plated, tin plated material, bearing steel, chilled castings, etc.

1.Electronic-driven instead of weight -driven, it can test the Rockwell and the Superficial Rockwell full scale;

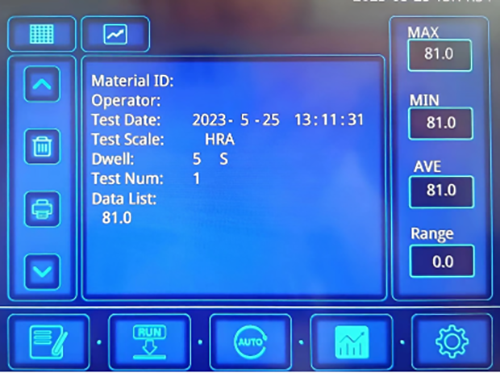

2.Touch screen simple interface, humanized operation interface;

3.Machine main body overall pouring, deformation of the frame is small, measuring value is stable and reliable;

4.Powerful data processing function, can test 15 kinds of Rockwell hardness scales, and can convert HR, HB, HV and other hardness standards;

5. Independently stores 500 sets data, and data will be saved when power is turned off;

6.Initial load holding time and loading time can be set freely ;

7.The upper and lower limits of hardness can be set to directly, display qualified or not;

8.With hardness value correction function, each scale can be corrected;

9. The hardness value can be corrected according to the size of the cylinder;

10. Comply with the latest ISO, ASTM, GB and other standards.

Main technical specifications:

Measuring range: 20-88HRA, 20-100HRB, 20-70HRC,70-100HRE, 50-115HRL, 50-115HRR, 50-115HRM

Initial test force :10kgf (98.07N)

Total test force: 60kgf (558.4N), 100kgf (980.7N), 150kgf (1471N)

The maximum height of the sample: 230mm

Throat: 170mm

Indenter: Rockwell diamond indenter, ф1.588mm steel ball indenter, ф3.175mm steel ball indenter, ф6.35mm steel ball indenter, 12.7mm steel ball Indenter

Test force application method: automatic (loading/staying/unloading )

Hardness resolution: 0.1HR

Hardness value display mode: Touch screen showing

Measuring scales : HRA, HRD, HRC, HRF, HRB, HRG, HRH, HRE, HRK, HRL, HRM, HRP, HRR, HRS, HRV

Conversion scale : HV, HK, HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HS, HBW

Execute Standard: ISO 6508,ASTM E-18,JIS Z2245,GB/T 230.2

Power supply: AC 220V/110V, 50/60 Hz

Dimensions: 475 x 200 x 700 mm

Weight: net weight about 60KG, gross weight about 84KG

|

Main Machine |

1Set |

ф1.588mm,ф3.175mm, ф6.35mm, 12.7mm ball Indenter |

Each 1 PC |

|

Diamond Cone Indenter |

1 PC |

Printer |

1 PC |

|

Anvil (Big, Middle, "V"-Shaped) |

TOTAL 3 PCS |

Adapter |

1 PC |

|

Plastic Rockwell Hardness Block(HRE, HRL, HRR, HRM) |

Total 4PCS |

Power Cable |

1 PC |

|

HRB Rockwell Hardness Block |

1 PC |

RS-232 Cable |

1 PC |

|

HRC (High, Low) Rockwell Hardness Block |

TOTAL 2 PCS |

Spanner |

1 PC |

|

Certificate |

1copy |

Packing List |

1 copy |