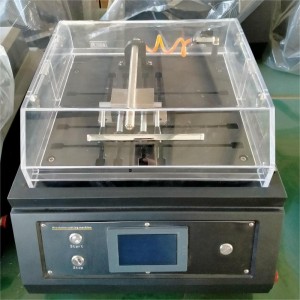

PQG-200 Metallographic Precision Flat Cutting Machine

PQG-200 metallographic precision flat cutting machine is suitable for cutting samples such as semiconductors, crystals, circuit boards, fasteners, metal materials, rocks and ceramics. The fuselage of the whole machine is smooth, spacious and generous, providing a good working platform. And adopts high torque and high power servo motor and infinitely variable speed control system, which has high working efficiency and stability. Good visibility and cutting ability minimizes operational difficulty and is easy to use. Moreover, the machine is equipped with a variety of different fixtures, which can cut irregular-shaped workpieces. It is a high-quality precision cutting machine suitable for scientific research institutions and enterprises.

PQG-200 type metallographic precision flat cutting machine is a flat pattern cutting machine developed for flat patterns. The equipment has a large transparent protective cutting room, which can observe the cutting process intuitively.

Electronic touch screen, adjust and control high-precision spindle, speed and spindle cutting speed and cutting distance, easier to use, easier to operate, with automatic cutting function, reduce the operator's work fatigue, and ensure the consistency of the sample cutting machine It is an ideal equipment for enterprises and scientific research institutes to prepare high-quality samples.

| product name | PQG-200 |

| Y travel | 160mm |

| cutting method | straight line, pulse |

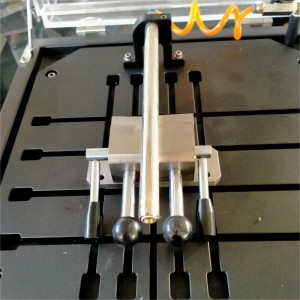

| Diamond cutting blade (mm) | Φ200×0.9×32mm |

| Spindle speed (rpm) | 500-3000, can be customized |

| Automatic cutting speed | 0.01-3mm/s |

| Manual speed | 0.01-15mm/s |

| Impact cutting distance | 0.1-2mm/s |

| Maximum cutting thickness | 40mm |

| Maximum clamping length of the table | 585mm |

| Maximum clamping width of worktable | 200mm |

| Display | 5 inch touch all-in-one computer control |

| How to use data | 10 types can be selected |

| Table size (W×D,mm) | 500×585 |

| power | 600W |

| power supply | Single-phase 220V |

| Machine size | 530×600×470 |

Water tank water pump: 1 set

wrench: 3pcs

Throat hoop: 4pcs

cut pieces: 1pc (200*0.9*32mm)

Cutting fluid: 1 bottle

Power cord: 1pc

1. This equipment can complete automatic cutting. Please set appropriate parameters according to the material to be cut before cutting.

2. Be sure to close the warehouse door before starting. If it is not closed, the system prompts that the warehouse door has been opened. Please close the warehouse door. During the cutting process, if the hatch door is opened, the machine will stop cutting. If you want to continue cutting, close the hatch door and press the start button. First, the water pump is running, and you can see that the pump running indicator lights up, followed by the spindle running and the spindle speed indicating The light is on, and finally the forward indicator light is on, and the cutting operation is carried out. For safety reasons, it is recommended not to open the door during machine cutting.

3. After the cutting is completed, the machine will automatically retract the knife and return to the original starting point. If the stop button is pressed during the cutting process, the machine will enter the state of retracting the tool and a message will prompt 'stop and exit'. To ensure safety, do not open the door during the retraction process.

4. If you need to replace the saw blade, please press the emergency stop button or turn off the main power switch and wait for a while for safety reasons. After the replacement, release the emergency stop or turn on the main power supply.

5. The system overload or clip saw alarm may be caused by the following reasons:

(1) The cutting saw blade is not suitable for this cutting material, and the cutting saw blade should be replaced at this time.

(2) The cutting speed is too fast, and the cutting speed should be reduced at this time.

(3) This cutting material is not suitable for this cutting machine.