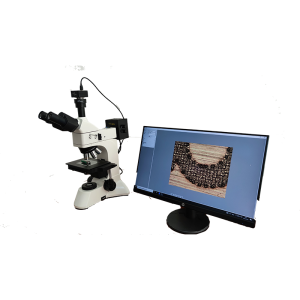

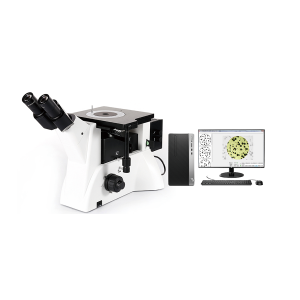

LH-FL8000W/8500W Upright Trinocular Metallurgical Microscopes

LH-FL8000W/8500W upright metallurgical microscopes are suitable for observation in the transparent or un-transparent object.

It equipped excellent UIS optical system and the notion of modularization function design, provide excellent optical performance and the update of the system, achieve synchronous transmission-reflecting light and independently illumination, polarization function.

The product has beautiful configuration, easy operation, clear image, so it is the perfect research instrument for the metal engineering, mineral engineering, precision engineering, electronics engineering etc.

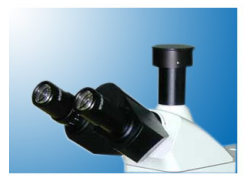

Eyepieces tube: 30°inclined;Trinocular can be connected to the camera;

10X wide field plan eyepiece: field of view number is Φ22mm, the eyepiece interface is Ф30mm

Objective: infinity plan achromatic objective;

Stage:

Double layer mechanical stage,

Overall size:210mm*140mm,

Moving range:63mm*50mm

Easy operation for operator

Drop lighting system

Halogen lamp (brightness can be adjusted), not only for the usual bright field observation method, but also for polarized light, dark field observation method to provide clear and vivid microscopic observation images. The built-in field of view diaphragm and aperture diaphragm can effectively control the field of view, adjust the field of view contrast, and the center of the field of view diaphragm is adjustable.

Transmission lighting system

Built-in halogen lamp lighting device: Using 6V30W halogen lamp (brightness is adjustable), can provide clear and vivid microscopic observation images. Light collector built-in field of view diaphragm, Abbe condenser N.A.1.25, up and down adjustable.

|

Technical specifications (standard) |

|||

|

Eyepiece |

10X wide field plan eyepiece and field of view number is Φ22mm, the eyepiece interface is Ф22mm |

||

|

Infinity plan achromatic objectives |

LH-FL8000W(Equipped bright field objective) LH-FL8500W(Equipped bright & dark field objective) |

PL L5X/0.12 working distance:26.1 mm |

|

|

|

|

PL L10X/0.25 working distance:20.2 mm |

|

|

|

|

PL L20X/0.40 working distance:3.98 mm |

|

|

|

|

PL L50X/0.70 working distance:3.18 mm |

|

|

|

|

PL L100X/0.80 (Optional) |

|

|

Eyepiece tube |

Trinocular inclined 30˚, pupil separation 53~75 mm. | ||

|

Focusing system |

Coaxial coarse/fine focus system, with tension adjustable device, minimum division of fine focusing: 2.0μm. |

||

|

Nosepiece |

Quintuple (Backward ball bearing inner locating) |

||

|

Stage |

Mechanical stage,overall size:210mmX140mm,moving range: 63mmX50mm |

||

|

Illumination system |

LH-FL8000W/8500W |

6V30W halogen and brightness enable control. |

|

|

|

Integrated field diaphragm, aperture diaphragm and puller type polarizer. |

||

|

|

Equipped with ground glass and yellow ,green and blue filters |

||

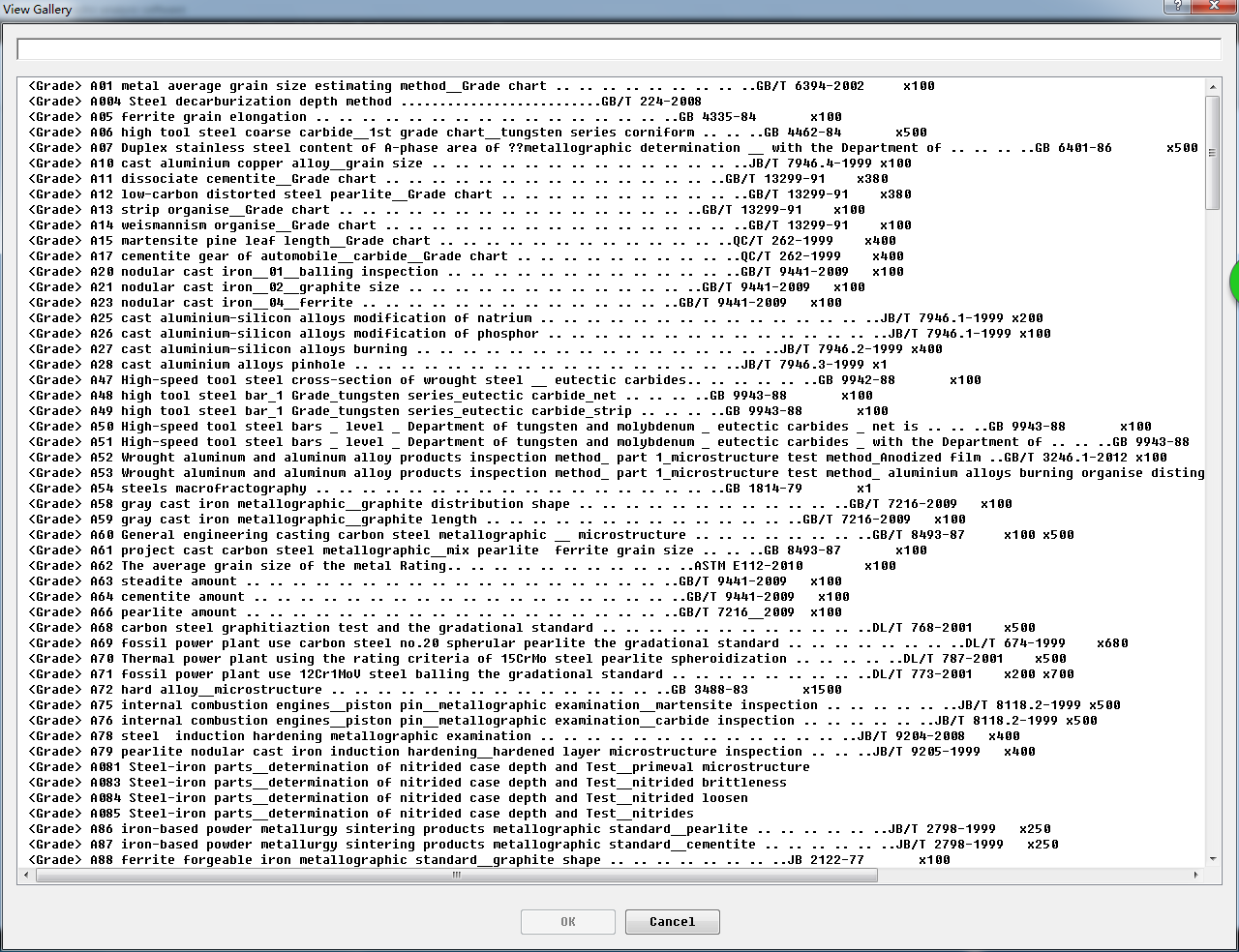

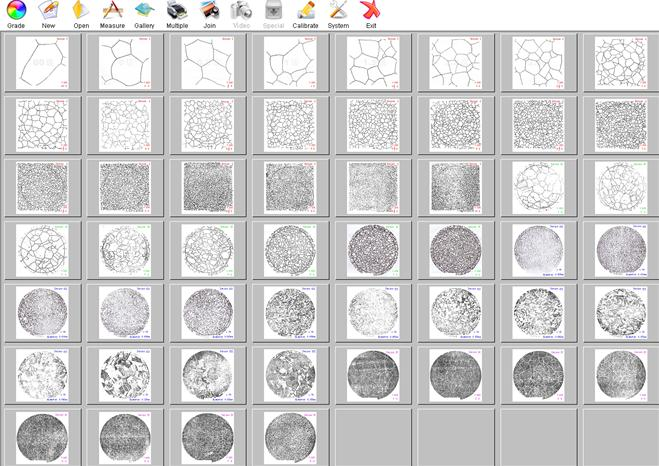

(2) Compare ratings Principle:

In comparison rating interface, software has three modes to choose from, each described below:

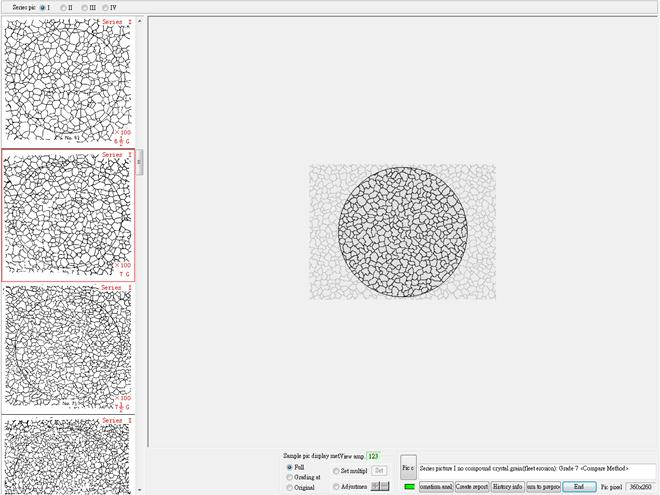

• "Full Window" mode:

Loading image, will be filled with the image display area on the right, so that the user can observe the loaded image detail. Screenshots are as follows:

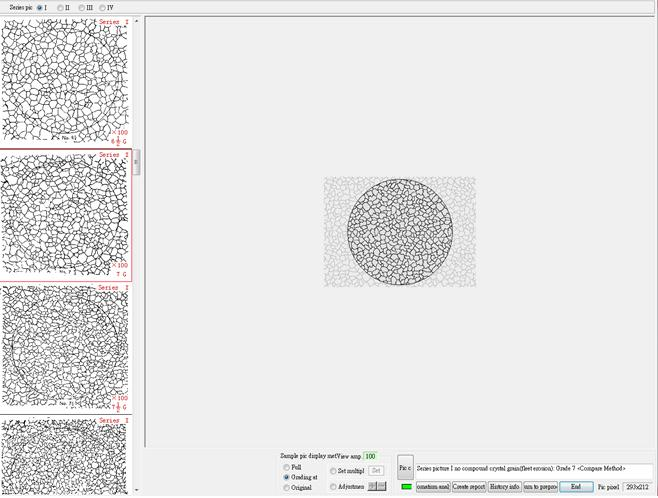

• "Atlas multiple" mode:

Loading the image, and the pattern left by the magnification power of the same size is displayed on the screen, the user can intuitively be loaded and the chart image in the image are compared, and the obtained level.

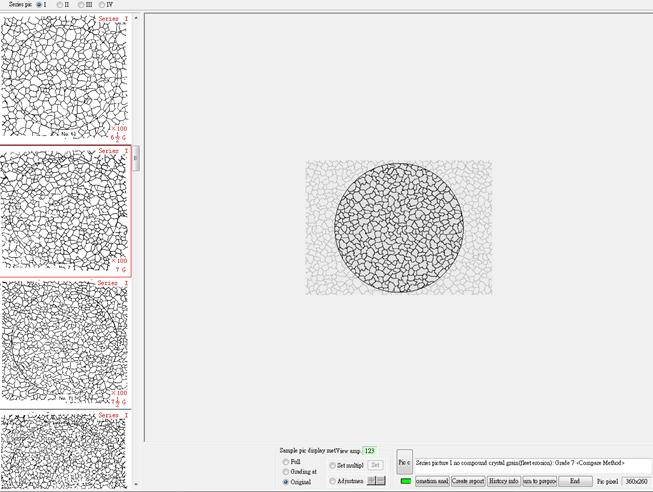

• "Original Size" mode:

Load the image, according to the size of the actual camera when, without any scaling to the display area on the right.

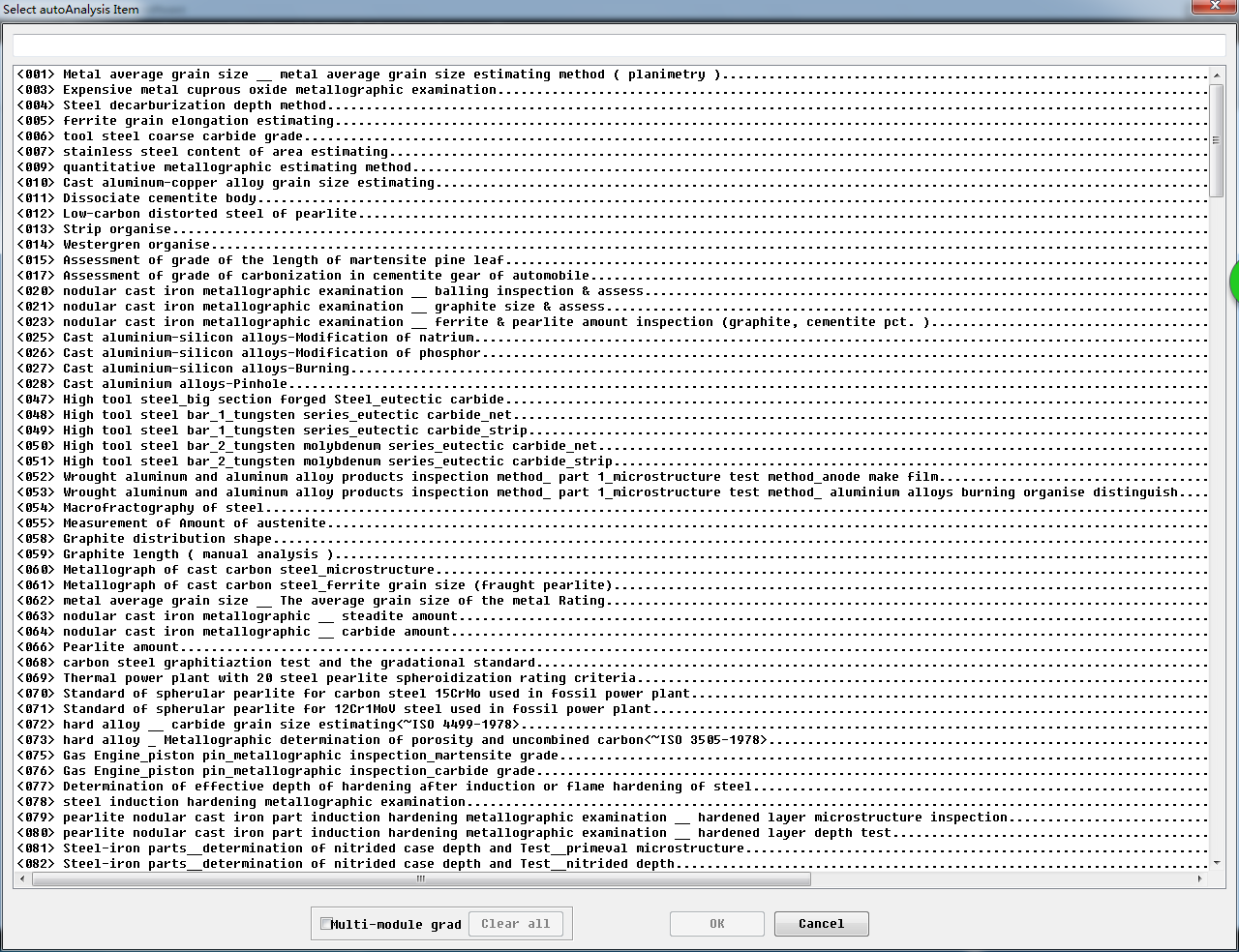

(1) Automatic rating

• Only when there is a quantitative criterion (such as formulas, percentage range, etc.) in the metallurgical standards, the module only with automatic rating feature.

• Because the actual sample preparation, the situation is more complex images captured almost impossible to make the same standard atlas image effects, therefore, requires the user to complete automatically when rating their own image processing, thresholding, etc., in order to find the microstructure associate.

• Automatic rating is to identify the microstructure, as long as identify the microstructure, the rating results necessarily correct.

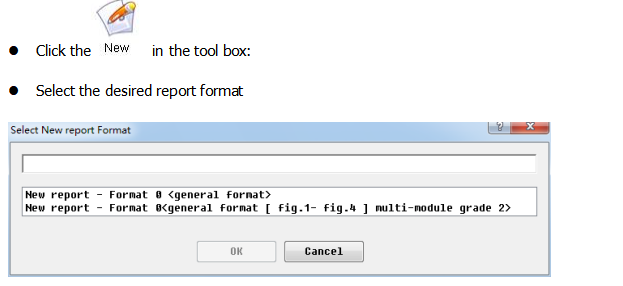

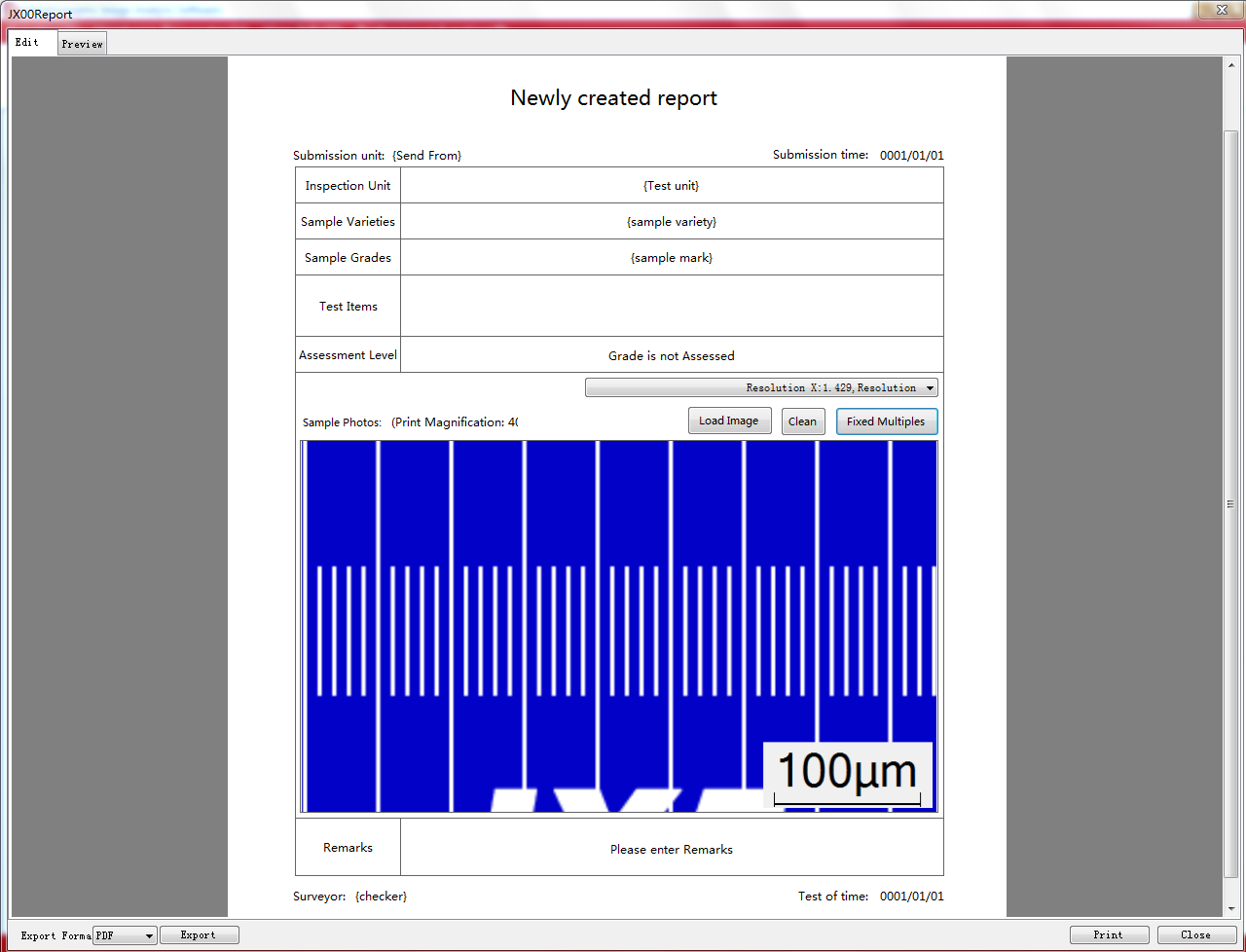

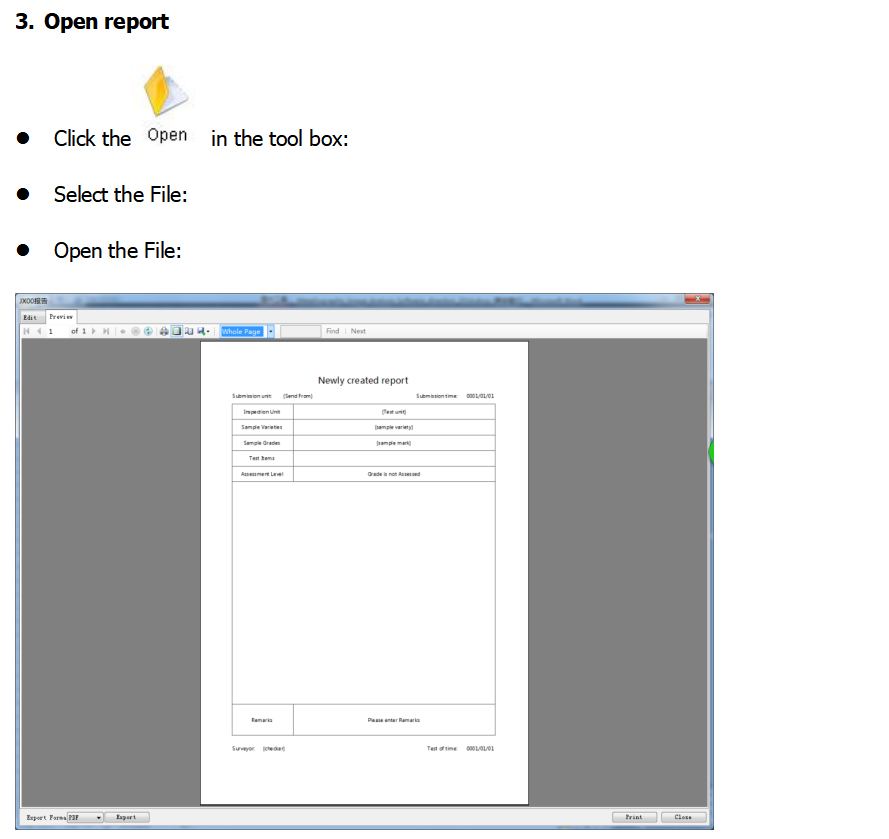

2. New report

• Once selected, click "OK" to enter the editing interface of image information:

• When loading an image, you need to select the image corresponding hardware parameters

• After completion of graphic information entered, you can export the report to PDF, WORD, EXCEL three formats:

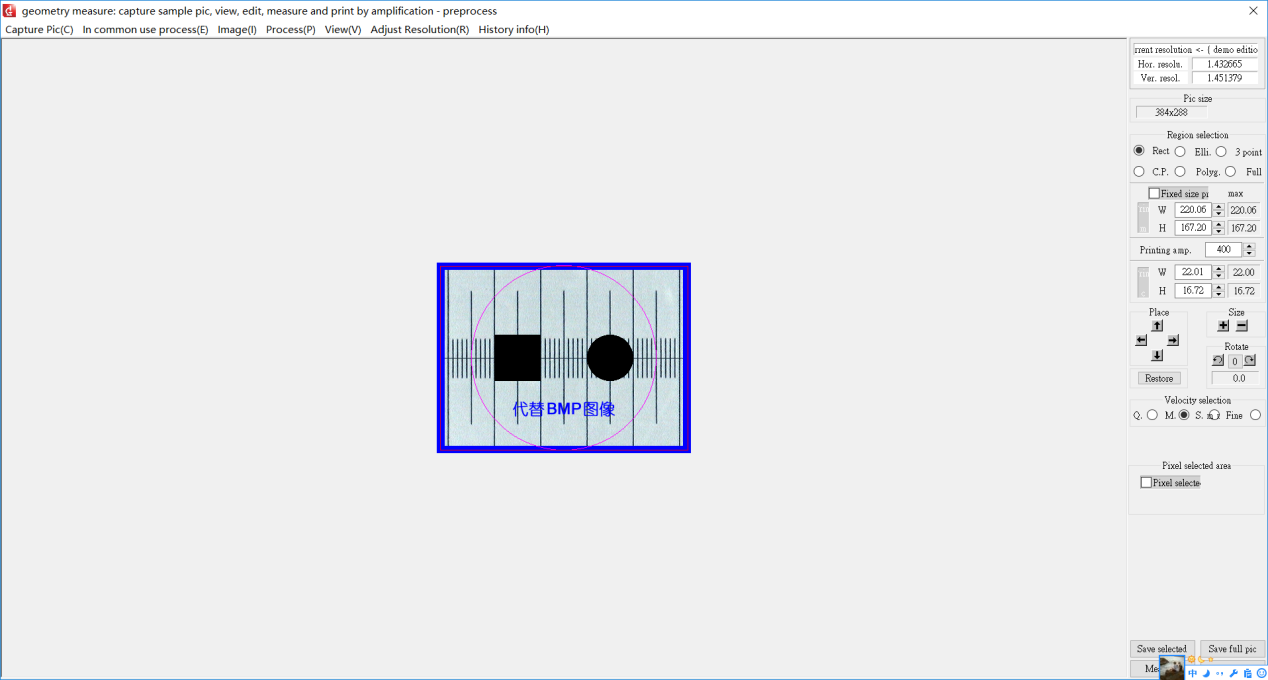

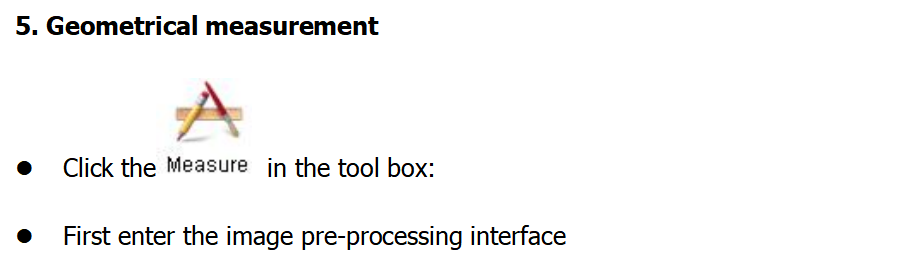

4. Image preprocessing

1) Commonly used treatment:

The software is often used image processing algorithms, To make a panel, Use rise more convenient.

2) Image processing:

Software provides the brushes, brightness adjustment, contrast and color adjustment, converted to gray image, gray levels, binarization processing, automatically reverse phase, sharpen, diffusion, median filtering de-noising, background brightness adjustment and background luminance equalization, RGB color separation, HLS color separation, gray level transformation, balanced, logarithmic increase, index of enhancement, linear enhancement, median smoothing and edge enhancement, edge detection, gradient, expansion, corrosion, opening operation and closing operation, critical binarization, threshold segmentation, critical threshold, accumulation threshold, the difference threshold, eliminate image processing tools such as a pen.

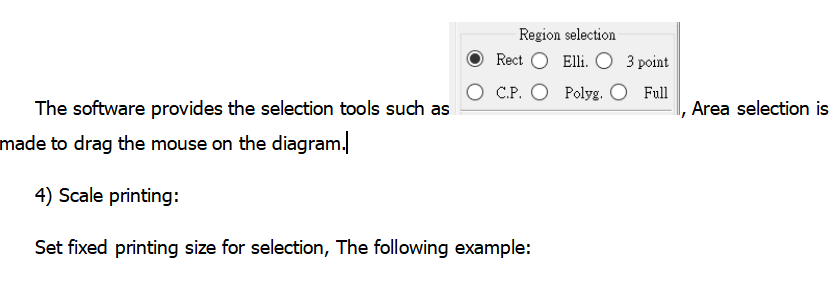

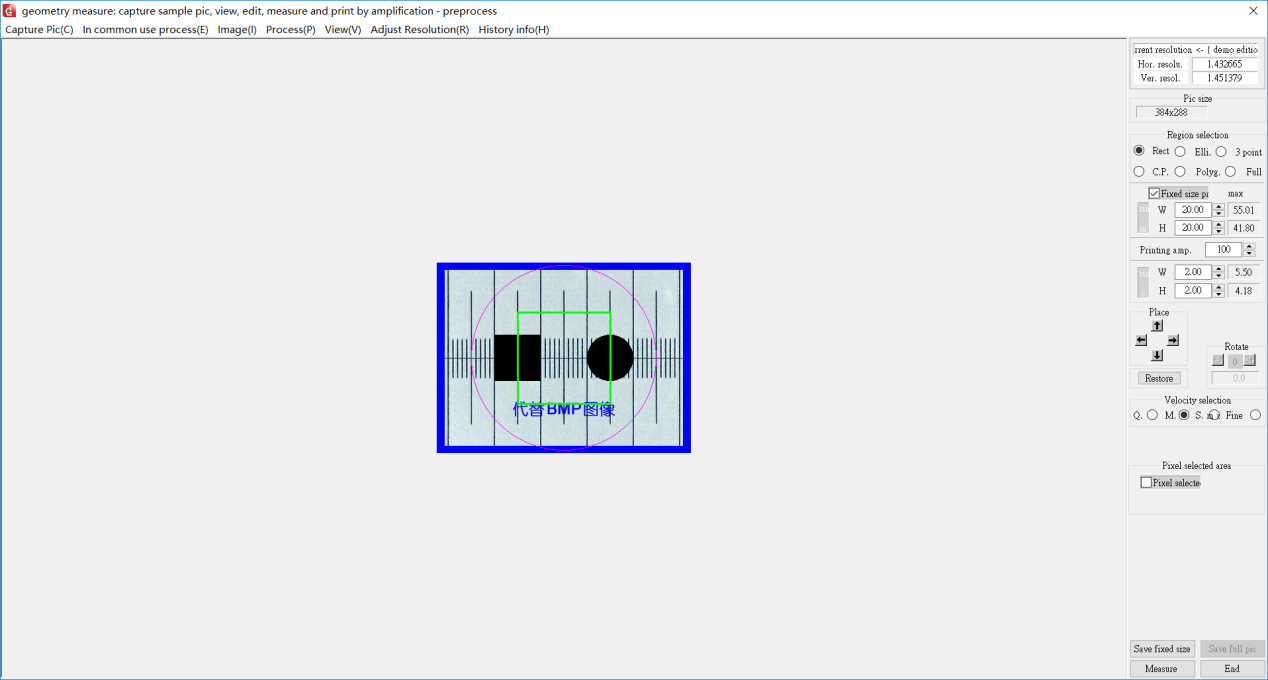

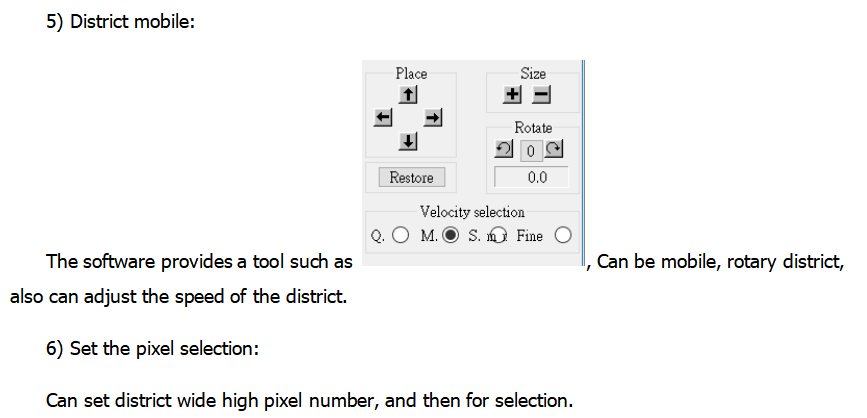

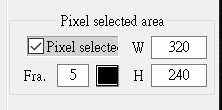

3) Regional options:

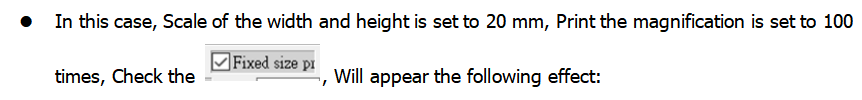

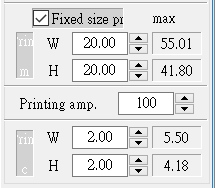

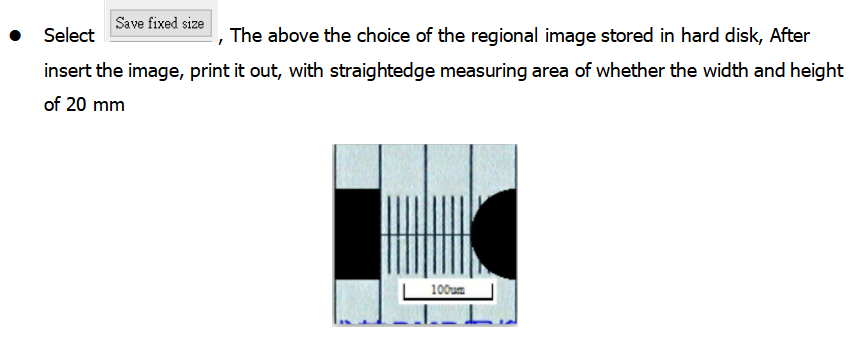

• According to the micrometer scale visible on the map, Green, the actual width of the rectangular area and the height is 200 us, Pour the push back(200um×100=20mm), Initial setup and the actual effect is the corresponding

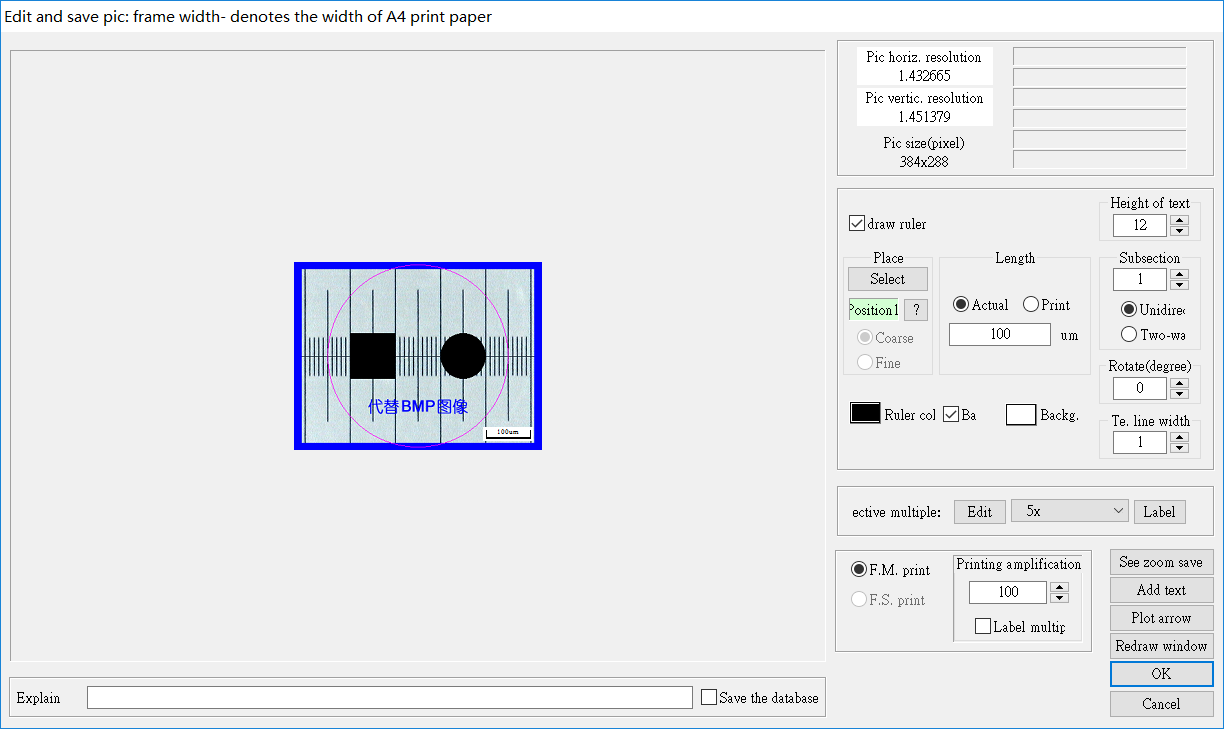

7) Save selection or full figure:

District part can be saved as a BMP or JPG image, save time, can set the print magnification of the image, can draw on figure scale, add text, draw the arrow, etc.

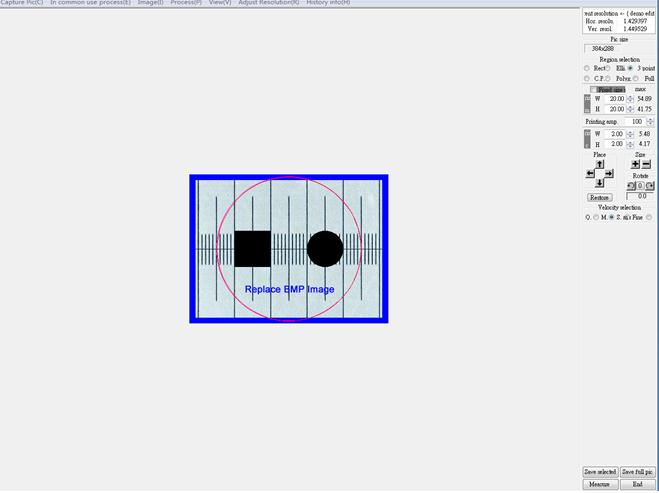

• Click on "Measure" button to enter the geometric measurement interface. This module provides a distance, rectangle, circle, polygon, angle, angle between two lines a variety of measurement tools, line, curvature, etc., can be done to measure the basic geometry:

• View Gallery:

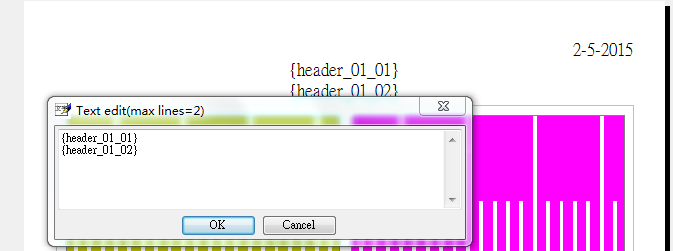

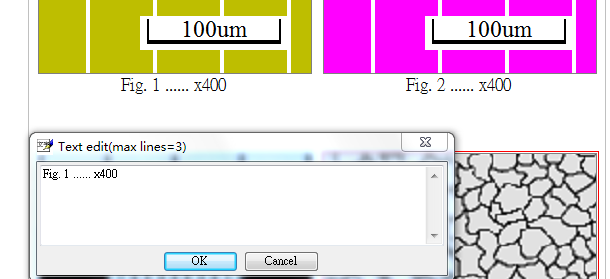

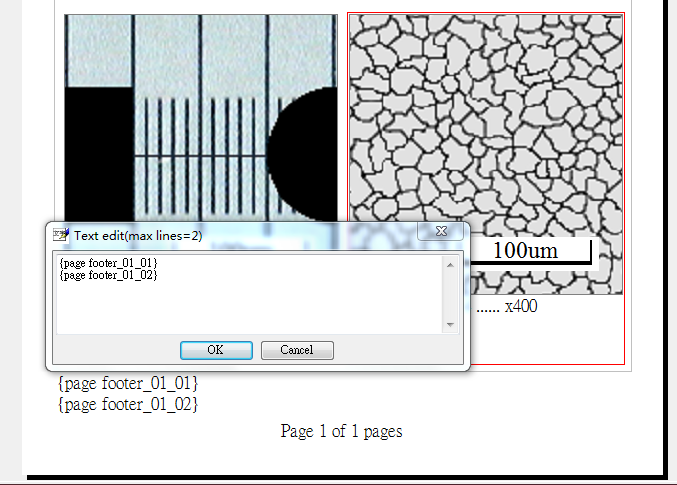

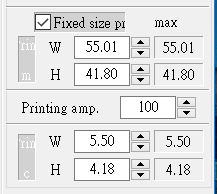

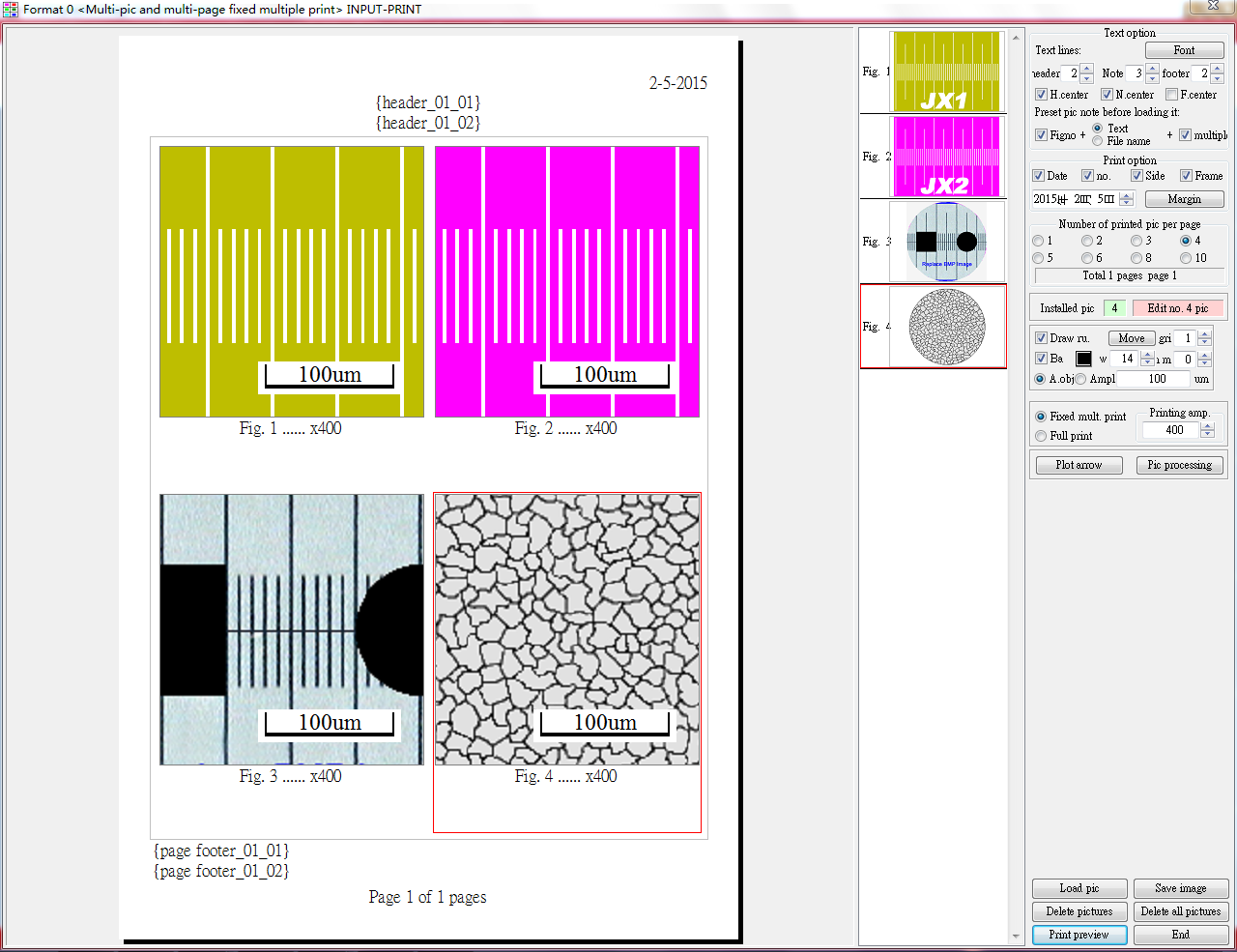

7. Fixed Multiple Print

• Move the mouse to the header, text area below the image, while the footer, the cursor will change, then click the right mouse button to bring up the text edit box.

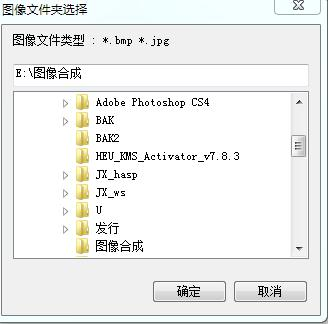

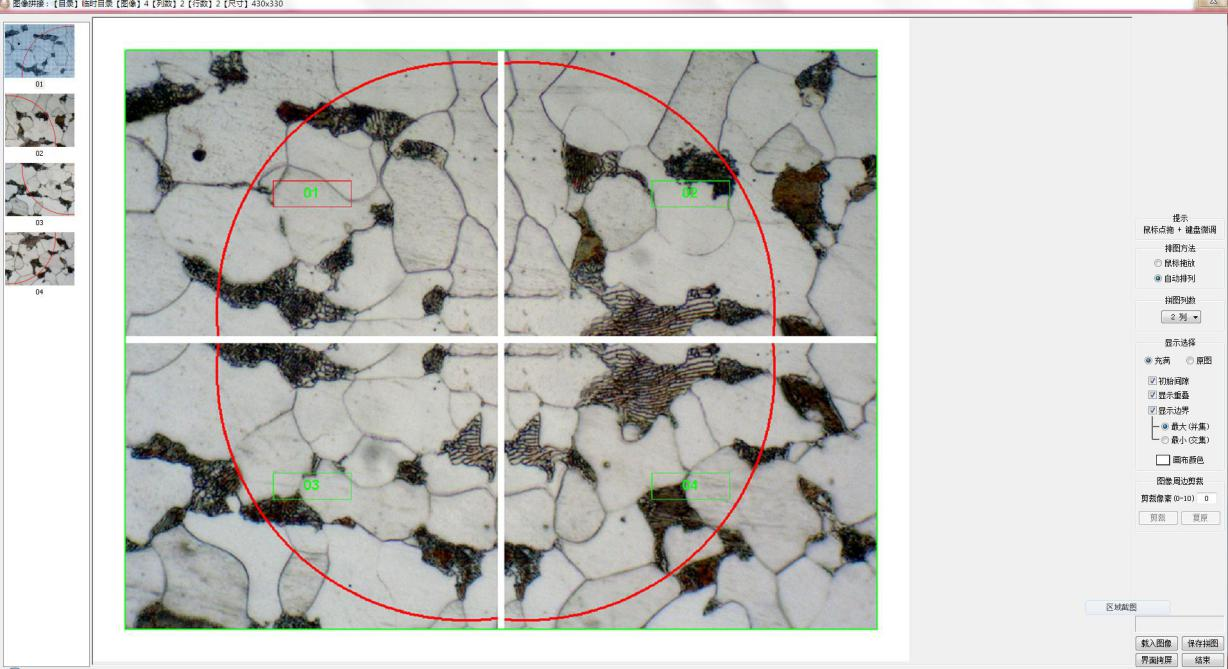

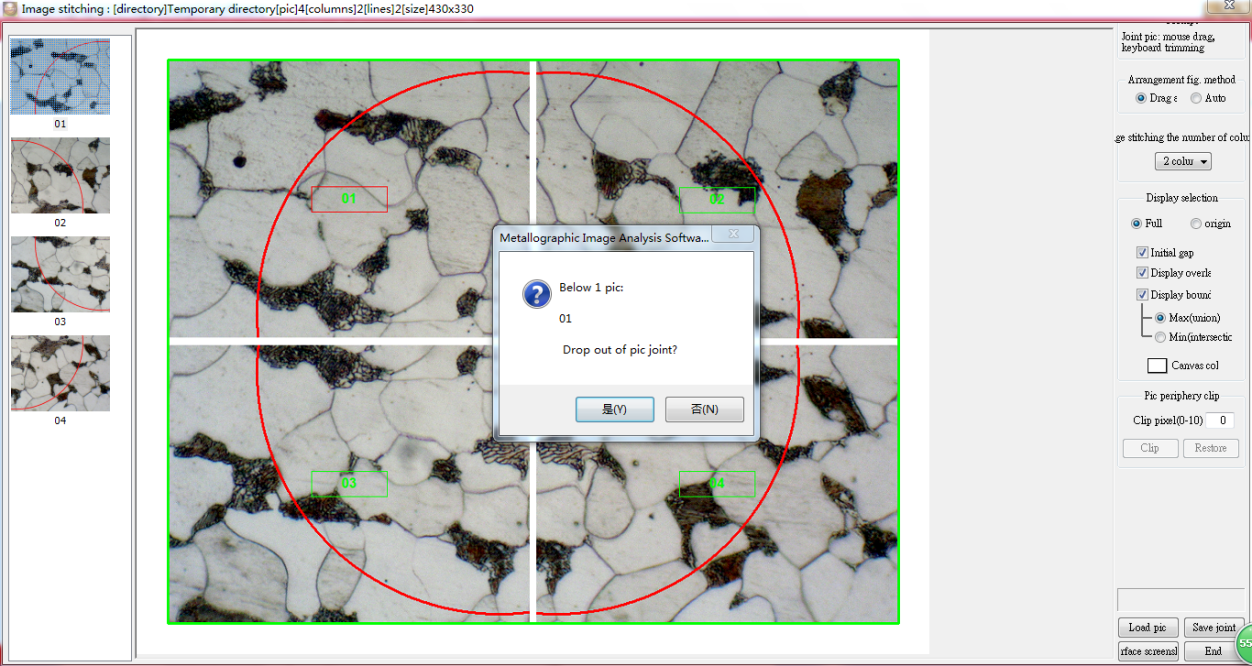

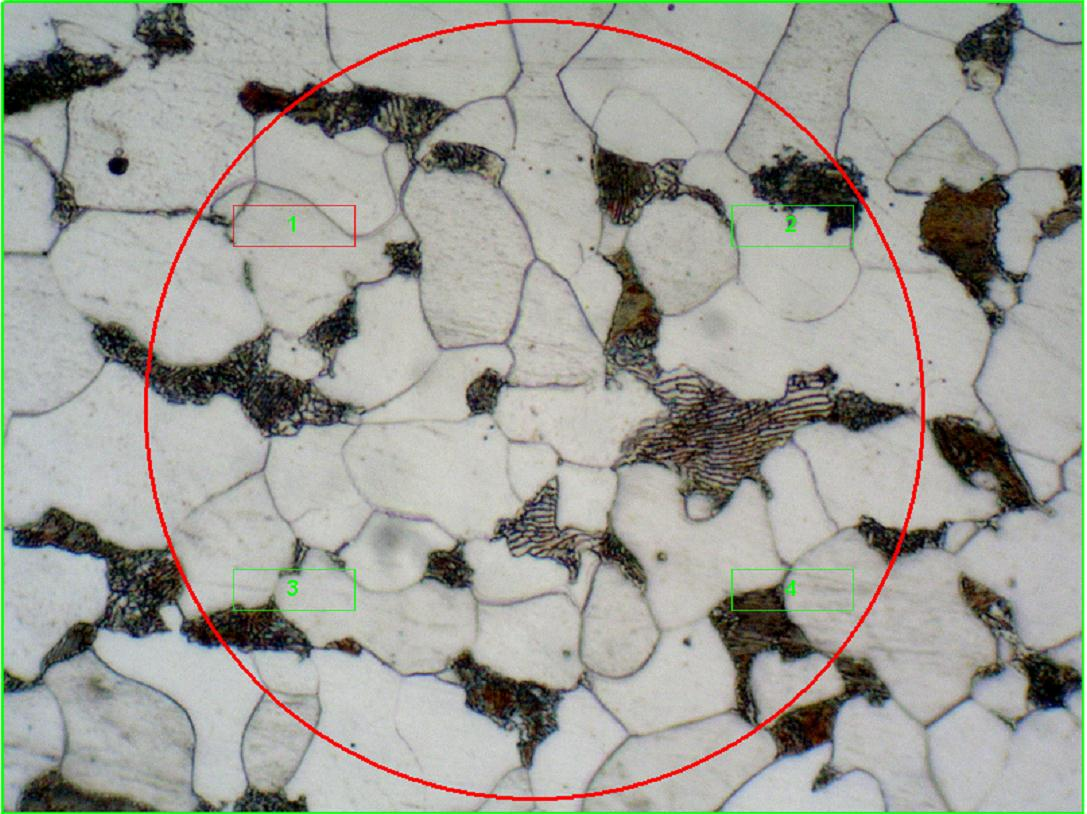

• After selecting the folder, click "OK" to enter the image synthesis of the main interface:

• After the image is loaded, displayed in the list on the left (see figure above), right-click on a sheet image, the maplike deleted from the list:

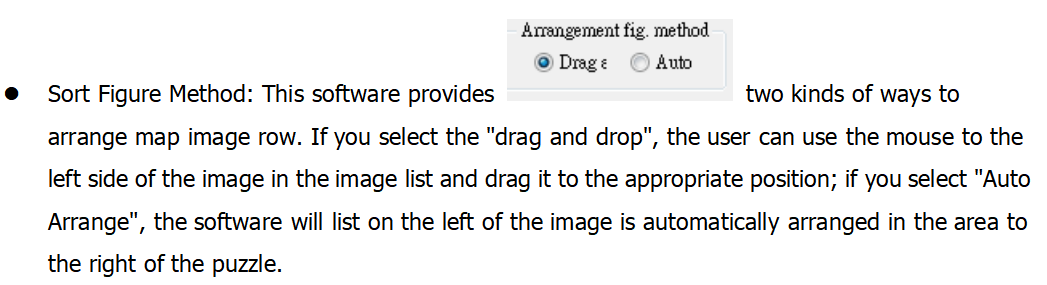

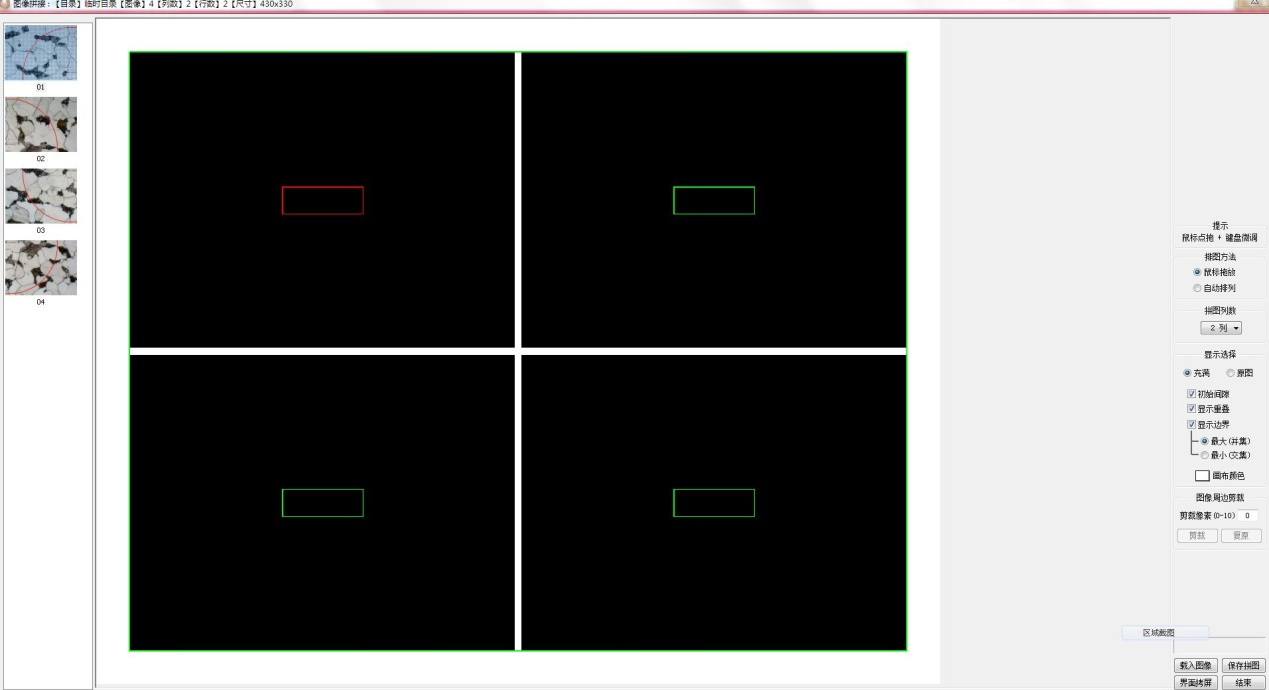

(The figure is select the "drag and drop" interface when)

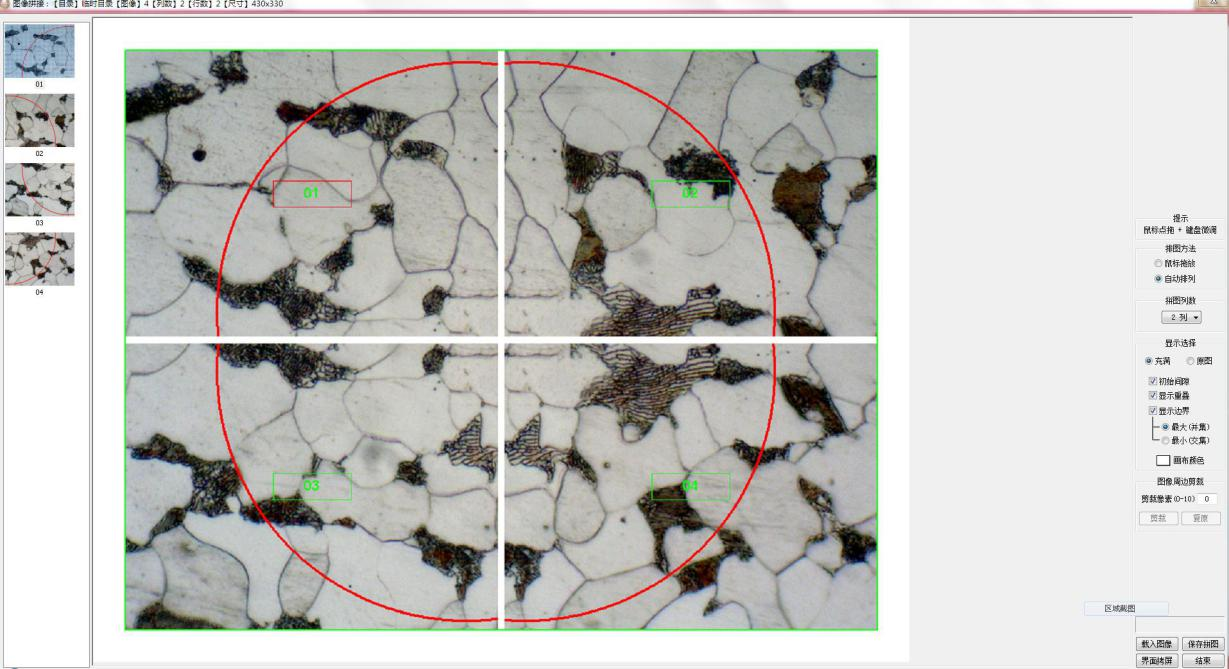

(The figure is to select "Auto Arrange" screen time)

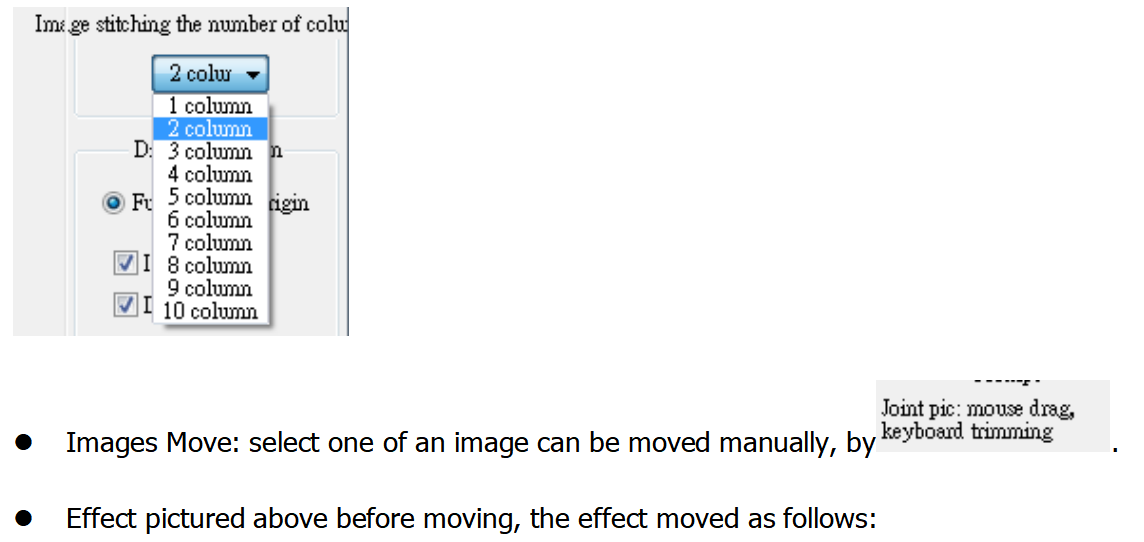

• Number of puzzle columns: column adjustment puzzle, image position will change accordingly to suit the requirements of different stitching software several preset number of columns:

• Display options: Display mode to select the image or picture is full.

• Initial gap: When an image is loaded choose whether to display the gap between images.

• Display overlap: When moving images, whether to show the overlapping portion of the shadow image.

• Display border: whether to display the image of a green border.

• Canvas color: Set the color puzzle floor.

• Cut Pixel: the edges of the image can be cropped.

3.9Video equipment

• This module provides the following function keys, the following function keys can be easily loaded static image files can also be used to select the video equipment to capture an image, then the image processing, and the processed image is saved.

3.10Specific modules