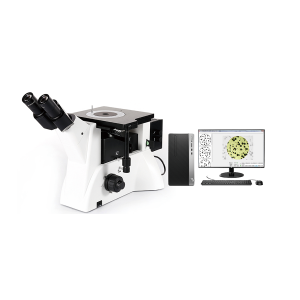

SC-2000C Welding penetration measuring microscope

The welding penetration detection microscope 2000C is equipped with a high-definition microscope and penetration measurement software, which can measure and save the penetration microscopic images produced by various welding joints (butt joints, corner joints, lap joints, T-shaped joints, etc.). At the same time, welding macro inspection can also be performed, and two microscopes are provided to inspect the welding quality. Welding penetration refers to the depth of melting of the base metal. During welding, there must be a certain penetration to make the two base metals to be welded firmly welded together. Insufficient penetration can easily cause incomplete welding, slag inclusions, weld nodules and cold Cracks and other problems.Too deep penetration can easily cause burn-through, undercut, pores and other phenomena, which directly affects the welding quality. Therefore, it is very necessary to measure the welding penetration. In recent years, with the rapid development of modern technologies such as electronics, chemicals, atomic energy, automobiles, shipbuilding, and aerospace, various industries have increasingly higher requirements for welding quality, and the detection of welding quality is crucial to the industrial upgrading of the machinery manufacturing industry. Crucial. The industrial upgrade of penetration microscope is imminent. In response to this situation, we have developed and designed a microscope HB5276-1984 for aluminum alloy resistance spot welding that measures welding penetration according to industry standards (HB5282-1984 Structural steel and stainless steel resistance spot welding and seam welding quality inspection). and seam welding quality inspection) welding quality inspection system 2000C. This system can not only measure the welding penetration (using the destruction method) but also check the welding quality, detect cracks, holes, uneven welds, slag inclusions, pores and related dimensions, etc. Macroscopic examination.

- Beautiful shape, flexible operation, high resolution and clear imaging

- The penetration depth can be accurately detected, a scale bar can be superimposed on the penetration depth image, and the output can be saved.

- Macroscopic metallographic inspection and analysis of welding can be performed, such as: whether there are pores, slag inclusions, cracks, lack of penetration, lack of fusion, undercuts and other defects in the weld or heat-affected zone.

GreenoughThe 10-degree convergence angle in the optical system ensures excellent image flatness under large depth of field. Careful selection of lens coatings and glass materials for the overall optical system can result in original, true-color viewing and recording of specimens. The V-shaped optical path enables a slim zoom body, which is particularly suitable for integration into other devices or stand-alone use.

The M-61's 6.7:1 zoom ratio expands the magnification range from 6.7x to 45x (when using a 10x eyepiece) and enables smooth macro-micro zoom to speed up routine workflows.

Proper inward angle provides the perfect combination of high flatness and depth of field for 3D viewing. Even thick specimens can be focused from top to bottom for faster inspection.

Extra large working distance

The 110mm working distance facilitates sample pick-up, placement and operation.

SC-2000C adopts 0.67X, 0.8X, 1.0X, 1.2X, 1.5X, 2.0X, 2.5X, 3.0X, 3.5X, 4.0X, 4.5X, 11 gear magnification indicators, which can accurately fix the fixed magnification. Provides a prerequisite for obtaining consistent and accurate measurement results.

| Model | SC-2000C Welding penetration measuring microscope |

| Standard magnification | 20X-135X |

| Optional magnification | 10X-270X |

| objective lens | 0.67X-4.5X continuous zoom, objective lens zoom ratio 6.4:1 |

| sensor | 1/1.8”COMS |

| resolution | 30FPS@ 3072×2048 (6.3 million) |

| Output interface | USB3.0 |

| Software | Professional welding penetration analysis software. |

| Function | Real-time observation, photography, video recording, measurement, storage, data output, and report output |

| mobile platform | Movement range: 75mm*45mm (optional) |

| Monitor size | working distance100mm |

| base bracket | Lift arm bracket |

| illumination | Adjustable LED lighting |

| Computer configuration | Dell (DELL) OptiPlex 3080MT operating system W10 processor chip I5-10505, 3.20GHZ memory 8G, hard drive 1TB,(optional) |

| Dell monitor 23.8 inch HDMI high definition 1920*1080 (optional) | |

| power supply | External wide voltage adapter, input 100V-240V-AC50/60HZ, output DC12V2A |